Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

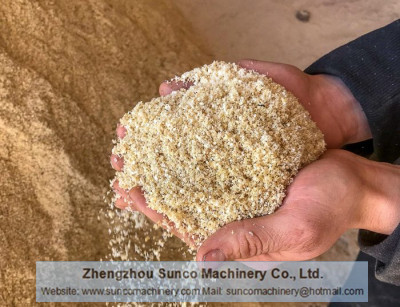

Airflow Sawdust dryer can reduce the sawdust s moisture content from 20-30% to 8%, Airflow Sawdust dryer mainly contains the air heater, feeder, air drying tube, cyclone, induced draft fan,etc It s also called flash sawdust dryer, biomass material dryers, etc

Technical Parameters

Airflow Sawdust Dryer Introduction:

◆ When making wood pellets or wood briquettes, the sawdust must be in 8%-15% moisture content. Actually, this moisture content of your sawdust will be a little higher or lower. Too high moisture content in your sawdust will make your production failed, and then the wood pellets or wood briquette will be in low density and easy to be broken.

◆ Airflow Sawdust Dryer also is named Airflow Sawdust Drying Machine, pipe dryer,flash dryer. Using one screw conveyor to send the wet sawdust into the air drying tube continuously, during the transport and dispersion of the high-speed hot air stream, the moistue of sawdust is lost, and finally we get the dried sawdust.

◆ Airflow sawdust dryer is considered as the most inexpensive sawdust dryer, simple in structure. After being dried, moisture content for sawdust can be reduced from 50% to 8%, which is suitable for pelletizing or briquetting. Airflow sawdust dryer is highly recommended for production capacity less than 1000kgs per hour.

◆ Airflow Sawdust Dryer mainly consist of air heater, feeder machine, air drying tube, cyclone separator, high pressure induced draft fan, etc.

Performance Features of Flash Sawdust Dryer :

◆ Large intensity of drying: Due to the material is highly scattered in the hot air, the total surface area of particles is the active drying area ;

◆ Short Drying Time ;

◆ Airflow Sawdust Dryer has compact structure, needs less floor area, easy to install and maintenance ;

◆ Large Handling Capacity, High Heat Efficiency. When drying the unbound water, the heat efficiency can be more than 60%.

◆ Biomass materials range and size: rice husk, wood sawdust, wood shavings, crushed tree branches, small wood chips, etc. Diameter is less than 3mm, length is less than 5mm.

◆ Thermal efficiency: Because the material is highly dispersed in the air flow, the contact area between the material and hot air is large, so the drying time is short, the processing capacity is large, and the thermal efficiency is high. When drying unbound water, the thermal efficiency can reach 60%.

◆ Fuel for heating: waste wood, coal, steam and electric heating.

◆ Installation space is small: The hot airflow dryer is pipe structure, it can be installed in line and also can be fold installation to save the space.

Airflow Sawdust Dryer Application:

Airflow sawdust dryer is widely used in straw briquette fuel, charcoal machinery, wood pellet fuel, sawdust briquettes, agricultural engineering industries. For example, the drying of agricultural fiber materials such as corn straw, soybean straw, cotton stalks, wheat straw, sorghum stalks, sawdust , wood shavings, ginkgo leaves, mulberry leaves, etc.

Airflow Sawdust Drying Machine Technical parameters:

| Model | Capacity | Power | Dimension | Weight |

| ASD220 | 300-400 kg/hour | 4kw | 2.25x1.1x1.3m 1.45x0.85x1.48m | 980kg |

| ASD320 | 400-600 kg/hour | 7.5kw | 2.40x1.8x2.0m 1.5x1.45x1.4m | 1480kg |

If you are interested in our Airflow sawdust dryer, please refer to:

◆ Video: http://www.youtube.com/watch?v=REUTsceDQw4&feature=youtu.be

◆ Email: suncomachinery@hotmail.com

◆ Mobile: +86-15838214261