Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

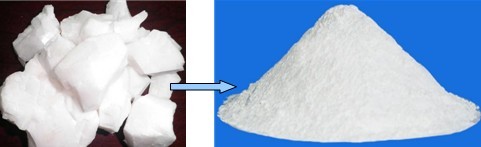

Calcium Carbonate Mill also is named calcium carbonate grinding mill Calcium Carbonate Mill is suitable for grinding calcium carbonate into fine powder

Technical Parameters

Calcium Carbonate Mill Brief Introduction :

Calcium Carbonate Mill also is named calcium carbonate grinding mill. Calcium Carbonate Mill (Raymond Mill) is suitable for grinding calcium carbonate into fine powder.

After being grinded by the Calcium Carbonate Mill, the fine powder size can be 40 mesh to 325 mesh for industry usage. The powder output size of Calcium Carbonate Mill (Raymond Mill)can be adjusted continuously according to the customers' demand.

Calcium Carbonate Mill Features:

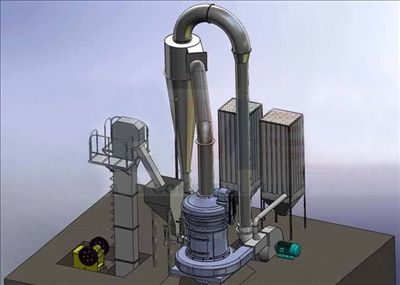

01. Vertical structure of strong systematic characteristic, occupies small area. From crushing of calcium carbonate to grinding and packing is an independent production system.

02. Passing ratio achieves 99%.

03. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

04. Main parts of the plant are made from cast and steel of high quality.

05. Centralized controlled electric control system , high automaticity, no people are needed in the operating room.

Calcium Carbonate Mill Principle :

01. Calcium Carbonate is crushed by jaw crusher to the smaller size which is suitable for the Calcium Carbonate Mill.

02. Then the crushed calcium carbonate are elevated into a hopper by bucket elevator,

03. The crushed calcium carbonate is transported through the vibrating feeder evenly and continuously into the grinding chamber of the calcium carbonate grinding mill (Raymond Mill). The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the calcium carbonate, send to the middle between ring and roller to accomplish the grind.

04. After this, the ground calcium carbonate are carried by the air from the blower into the powder separator (Analyzer Machine) for screening. The fine calcium carbonate powders are blow into the cyclone powder collector and are poured out through the output-powder valve as the final products, and the corase calcium carbonate after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

Calcium Carbonate Mill Main Technical Data :

| Model | Roller Number | Roller Size (mm) | Max. Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Mainframe (kw) | Blower (kw) | Overall Size (mm) |

| QBM6515 | 3 | 210X150 | 12-20 | 0.613-0.033 | 0.25-2.0 | 15 | 11 | 4100X3300X4500 |

| QBM7815 | 3 | 260X150 | 15-20 | 0.613-0.033 | 0.28-3.0 | 18.5 | 15 | 4300X3500X5100 |

| QBM3016 | 3 | 300X150 | 15-20 | 0.613-0.033 | 0.35-4.0 | 22 | 18.5 | 5300X4100X5200 |

| QBM9517 | 4 | 310X150 | 15-25 | 0.613-0.033 | 1.5-8.0 | 37 | 37 | 7100X5900X7900 |

| QBM4121 | 5 | 410X210 | 15-25 | 0.613-0.044 | 5.0-12.0 | 75 | 75 | 7850X8000X9700 |

| QBM4528 | 6 | 450X280 | 15-25 | 0.613-0.044 | 5.0-22.0 | 132 | 132 | 12550X5700X8300 |

Notice: Any change of Calcium Carbonate Mill (Raymond Mill) technical data shall not be advised additionally.

If you are interested in our Calcium Carbonate Mill, please refer to:

◆ Email: suncomachinery@hotmail.com

◆ Mobile/WhatsApp: +86 15838214261

◆ Video: https://www.youtube.com/watch?v=OEY6sF_TbpM

https://www.youtube.com/watch?v=mKndTS0SpOI