Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

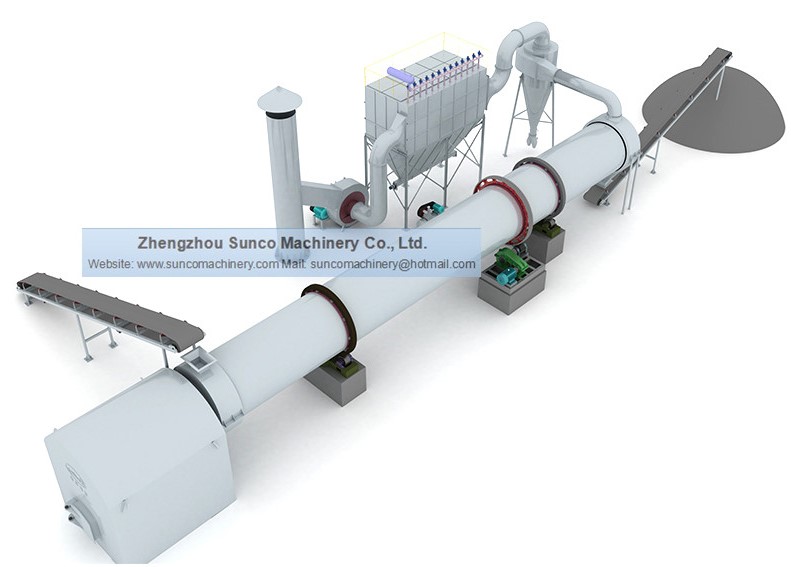

Quartz Sand Dryer is specially designed to dry the wet silica sand, and get rid of the water from wet silica sand. With the help of the quartz sand dryer, the moisture content of the silica sand can be less than 1% or even bone dry.

Then, What is the working principle of the quartz sand dryer ?

Firstly, use one belt conveyor or bucket elevator to send the wet silica sand into the drum of quartz sand dryer.

On the inner wall of the cilinder/drum, there are many lifting plates which is welded with special height and angles. When the Quartz Sand Dryer's drum is rotating, these lifting plates makes the silica sand up and down to mix with the hot air completely. Durng this process, the moisture is evaporated. Here the hot air temperature can be up to about 400-500 centigrade.

On the another side of the quartz sand dryer, there is one high pressure induced fan which sucks out the exhaust air and vapor, and then the exahsut air goes into the cyclone dust separator.

In the cyclone dust separator, the dust inside the exhasut air falls down and goes out through the discharging hole of the cyclone dust separator. The exhasut air goes into atmosphere directly through the chimney which is connected to the cyclone dust separator.

Furnace for the silica sand dryer usually has two types. For the handling capacity below 30 t/h, our company's new design hot air furnace is very suitable. We have produced well the hot air furnace at our factory, and later when the user gets the hot air furnace, the user only need to connect the hot air furnace to the silica sand dryer directly by themselves. It will save the user much time and cost.