Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

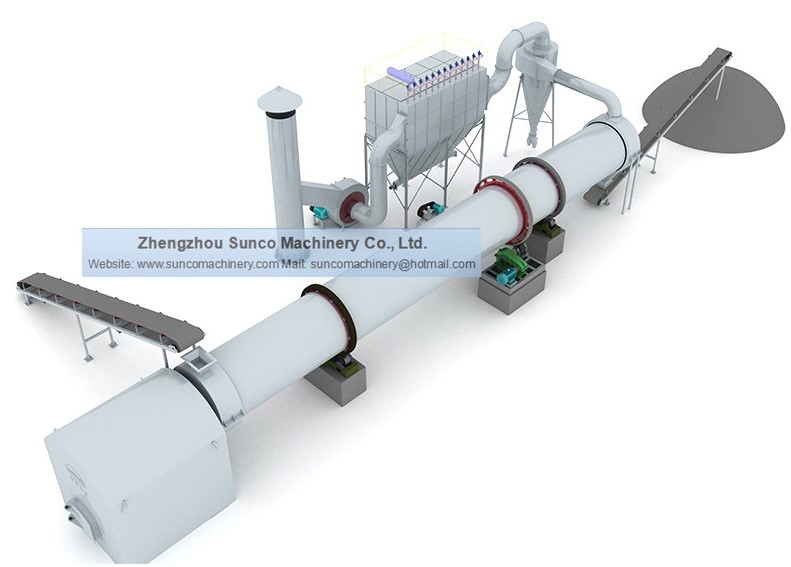

Rotary dryer is a critical part of industrial equipment used to reduce the moisture content of various materials, for Sunco Machinery, we are experienced in the drying field of chicken manure, silica sand, river sand, slag, hay, wood shavings, sawdust, wood chips, fly ash, olive pomace, etc.

Proper design of a rotary dryer is crucial for efficient operation, maximizing productivity, and ensuring that the end product meets specific moisture content requirements. This article will illustrates the key considerations and steps involved in selection and design of a rotary dryer correctly.

What is a Rotary Dryer?

A rotary dryer consists of a large, rotating cylindrical drum through which the material to be dried passes. Heat is applied either directly or indirectly to evaporate moisture. The dried material is then discharged at the outlet end of the drum. The design of a rotary dryer involves determining the optimal dimensions and operational parameters to achieve the desired drying performance.

Key Factors in Selection and Design of a Rotary Dryer

>>> Material Characteristics

1. Moisture Content: The initial and output moisture content of the material will influence the amount of water that needs to be evaporated.

2. Loose Bulk Density: This affects the volume of material that can be processed.

3. Particle Size Distribution: Uniform particle sizes can be dried more evenly, while varied sizes may require additional considerations.

4. Heat Sensitivity: Some materials may degrade at high temperatures, necessitating lower drying temperatures and longer drying times.

>>>Production Capacity

Determine the amount of material to be processed per hour. This will directly impact the size of the dryer needed to handle the desired drying capacity.

>>> Air Flow Quantity and Drying Temperature

1. Inlet Hot Air Temperature: Higher temperatures generally increase drying rates but may not be suitable for heat-sensitive materials.

2. Air Flow Volume: Sufficient airflow is needed to carry away evaporated moisture. The volume of air should be matched to the heat input and moisture quantity, too more or too less air flow volume both are not good to the drying efficiency.

3. Exhaust Air Temperature: This should be optimized to ensure efficient drying without overheating the material. Usually the exhaust air temperature is less than 80 centigrades.

>>> Drying Time

The time the material passes through rotary dryer drum is critical for ensuring complete drying effect. Drying time depends on the dryer’s length, drum rotation speed, and the internal structure (e.g., lifting flights that lift and disperse the material).

Steps to design a Rotary Dryer

>>>Calculate the Heat Requirement needed

1.Energy Balance: Determine the energy required to evaporate the water needed. This involves calculating the sensible heat required to raise the material and water to the drying temperature and the heat needed for water vaporization.

2. Heat Transfer Efficiency: Consider the efficiency of heat transfer from the heating medium to the material.

>>>Determine the Rotary Drum Size

1. Volume of the Rotary Drum: Based on the desired drying capacity and drying time, calculate the required volume of the drum.

2. Diameter and Length: Decide on the appropriate drum diameter and length to achieve the calculated volume. A common rule of thumb is to have a length-to-diameter ratio of 4:1 to 10:1, depending on the specific drying requirements.

3. Select the Drum Speed

The rotational speed of the drum affects the drying time and the heating of the material. Typical speeds range from 0 to 8 RPM. Slower speeds increase drying time but meantime may reduce drying capacity.

>>> Design the Internal Structure

Flights and Lifting Mechanisms: These are critical for ensuring uniform drying by lifting and disperse the material through the hot air. The design and arrangement of lifting flights should be optimized based on the material’s features and desired drying efficiency.

>>> Consider the Air Flow System

1. Air Inlet and Outlet: Ensure proper design of the air inlet and outlet to facilitate adequate air flow and efficient removal of moisture-laden air.

2. Dust Collection: Implement dust collection systems if the material generates dust during drying to maintain a safe and clean working environment. As the actual need, usually can use water scrubber or pulse bag filter, etc.

Looking to Install a Rotary Dryer?

Properly sizing a rotary dryer is a complex task that requires a thorough understanding of the material characteristics, production requirements, and the principles of heat and mass transfer. By carefully considering these factors and following a systematic approach, you can design a rotary dryer that meets your specific needs, ensuring efficient and cost-effective drying operations.

For one suitable rotary dryer, it is necessary to purchase it from the professional manufacturer like Sunco Machinery, and the necessary information needed are as follows:

1. What material do you need to dry ?

2. What is the usual praticle sizes of the material ?

3. What is the loose bulk density of the material ?

4. What is the initial moisture content (%) of the wet material?

5. What is the output moisture content (%) of the dried material?

6. What is the drying capacity (ton per hour) of the rotary dryer ?

7. What kind of fuel will you prefer to use such as coal, diesel, natural gas, biomass fuel, etc ?