Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

How to deal with chicken manure in large chicken farms? Treatment measures for chicken manure in large-scale chicken farms

1. Drying method

Drying methods can be further divided into three types: high-temperature rapid drying, mechanical drying, and natural drying. High temperature drying requires heating in a continuously running dehydration dryer. At a high temperature of 500 degrees Celsius, the moisture content can be reduced to below 13% in a short period of time, which can be used as feed. Natural drying is commonly used by farmers. Rice bran is added to chicken manure and exposed to sunlight. After drying, impurities are screened out and placed in bags or in a dry place for later use.

2. Fermentation method

Fermentation methods can be further divided into plate fermentation, lees fermentation, and mechanical fermentation. Mixed fermentation is the process of mixing chicken manure and other feed in a certain proportion and fermenting them. Fresh chicken manure, rice bran, and crushed green feed each account for one-third of the total, mix well, spray clean water until it reaches about 60%, put it into a tank or brick pond, compact it, and seal it with a plastic cloth. Mechanical fermentation is the use of chicken manure to regenerate feed fermentation machines, which can achieve the fermentation goal in half a day. The fermented chicken manure appears yellow brown, loose, and has a slightly sour and sweet taste, suitable for small and medium-sized chicken farms.

3. Biogas fermentation method

Chicken manure is one of the raw materials for biogas fermentation, especially chicken manure with water, which can be used to produce biogas. Establishing small and medium-sized fermentation tanks can produce biogas after 10-20 days of fermentation. Biogas can be used for heating in daily life, while biogas residue can be used as bait or fertilizer.

4. Silage method

Using fresh chicken manure of 50-65%, a mixture of chopped green feed, nuclear forage feed of 25%, and rice bran of 10%, with a moisture content controlled at around 60%. After compaction and sealing, it can be used within 30-45 days for feeding cattle, sheep, and pigs.

5. Expansion method

The puffing method, also known as the hot spraying method, involves drying fresh chicken manure to a moisture content below 30%, then placing it in a sealed puffing equipment, heating it to around 200 degrees Celsius, with a pressure of 8-15kg per square meter. After 3-4 minutes of treatment, the chicken manure is quickly sprayed out, and the volume can be increased by about 30% compared to the original. This method has excellent processing effect, fluffy and palatable, rich in aroma. The organic matter digestion rate increases by about 10%.

6. Direct feeding method

Fresh pure chicken manure can be directly fed to pigs or fish, and different effective ingredients can be added according to the content of different chicken manure during feeding. For example, young chicken manure with high crude protein content can be used as fine feed, while laying chicken manure with high ash content should be added with attention. When feeding pigs, fresh pure chicken manure is added directly to the daily feed at a ratio of 15%. On average, one pig can consume about 8? Feces from 10 adult chickens. When feeding fish, add them directly to the fish pond.

7. Air drying and crushing method

Spread and dry fresh chicken manure in a plastic greenhouse, with a layer thickness of less than 15 centimeters. Stir with a nail toothed rake and blow with a high-speed blower. After drying, chicken manure is crushed and processed into pellet feed, which can be fed to cows, sheep, and poultry, with a general addition amount not exceeding 20%.

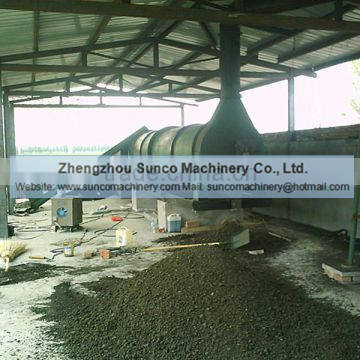

The most high efficiency chicken manure drying methods is to use high temperature hot air to heat and dry the wet manure quickly and continuously. The temperature of hot air can be up to about 400 centigrade, under such high temperature, not only the chicken manure can become dry quickly, and the moisture content can drop to be less than 20% within abot 20 minutes, but also the bacterials, germs, etc are killed.

The key equipment for such type manure drying methods is chicken manure dryer machine, and it is developed and optimized on the base of rotary drum dryer. It is very suitable for large scale chicken layer farm.

For the chicken manure dryer, you can choose the most cheap fuel such as waste wood, coal, diesel, or natural gas, etc according to your local market.

For detailed offer of chicken manure drying machine, you are welcome to contact Sunco Machinery for detailed informaiton.