Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

1. Advantages of Rubber Wood Particleboard

1.1 Environmental protection

Rubber wood particleboard is made from rubber wood as raw material, which grows naturally and is pollution-free, therefore it has good environmental performance. The use of rubber wood particle board can effectively reduce environmental pollution and protect our ecological environment.

1.2 Durability

Rubber wood particle board has good durability, high hardness, strength, wear resistance, moisture resistance, mold resistance, corrosion resistance, and long service life. Therefore, this material is suitable for making furniture, flooring, etc. that require high durability.

1.3 Easy to process

Rubber wood particleboard is easy to process and can be processed into various shapes such as cutting, drilling, carving, etc. according to needs. Therefore, rubberwood particleboard can be used to make furniture and decorations of various shapes.

1.4 Anti corrosion

Rubber wood particleboard has good anti-corrosion function.

2. Disadvantages of Rubber Wood Particleboard

2.1 The price is relatively high

The price of rubber wood particleboard is relatively high, slightly more expensive than ordinary wooden materials. However, considering the environmental friendliness and durability of the material, its overall cost-effectiveness is still relatively high.

2.2 Easy to get damp

Due to the high molecular moisture content of rubberwood particleboard, it is prone to moisture absorption, mold and deformation. Therefore, when using rubberwood particleboard, special attention should be paid to moisture prevention and timely handling of moisture issues.

3. Scope of application of rubber wood particle board

Due to its good durability, corrosion resistance, and ease of processing, rubber wood particle board is suitable for various occasions, such as:

3.1 Create durable furniture such as dining tables, chairs, beds, etc.

3.2 Produce high-end flooring, wall panels, etc.

3.3 Produce interior decoration materials such as doors, windows, cabinets, etc.

3.4 Create artworks, sculptures, etc.

In short, rubberwood particleboard is a high-quality material that is environmentally friendly, durable, corrosion-resistant, and easy to process. It has a wide range of applications, but attention should be paid to moisture prevention.

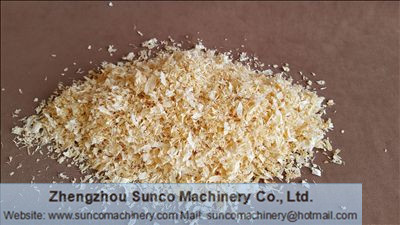

For making rubberwood particleboard, the high quality dry wood shavings is necessary, then how to dry the wet wood shavings in bulk production quickly ?

Wood Shavings dryer by Sunco Machinery is optimized on the base of rotary drum dryer, and it is ideal for drying wood shavings quickly and continuously in large quantity.

Wood shavings dryer machine adopts high temperature hot air drying mode, and within about 20-25 minutes, it can reduce the moisture content of wet wood shavings from 40-50% to be less than 15% or as need.

If you are in need of wood shavings drying machine, please feel free to contact Sunco Machinery at your convenience, and here we will prepare the detailed offer for you accordingly.