Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Silica Sand Dryer Machine from Sunco Machinery is ideal or drying mineral material such as slag, river sand, silica sand, etc. Silica sand dryer mainly has two types, one is single pass sand dryer, one is triple pass sand dryer.

For single pass silica sand dryer, it is traditional rotary drum dryer, and during the drying process, the quartz sand only pass through the dryer cylinder one time, thus its drying time is limited, and its heat efficiency is lower. But for single pass silica sand dryer, it is cheaper.

For Triple Pass silica sand dryer, its inner structure is more reasonable, and during the drying process, the quartz sand pass through the dryer drum 3 times, and come to the high temperature zone two times. Thus, the drying time is more longer, and its heat efficiency is higher, and the related fuel consumption is lower.

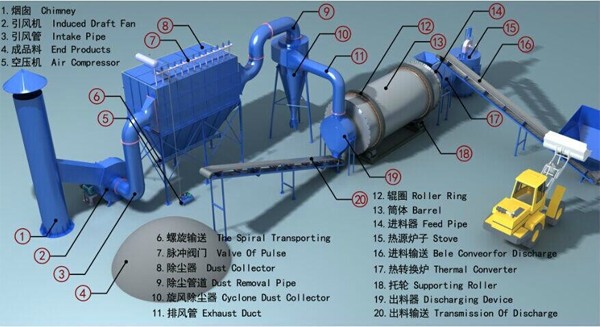

Silica Sand Dryer Working Process is as follows:

>>> Burner and hot air furnace supply the high temperature flue gas for the silica sand drying process.

>>> Input belt conveyor or bucket elevator to send the wet silica sand into the drum of silica sand dryer.

>>> On the inner wall of the cilinder/drum, there are many lifting plates which is welded according to one special methods. When the Silica Sand Dryer's drum is rotating, these lifting plates makes the silica sand up and down to mix with the hot air completely. Durng this process, the moisture is evaporated.

>>> On the another side of the silica sand dryer, there is one high pressure draught fan which sucks out the steam, and then the steam goes into the cyclone dust separator.

>>> In the cyclone dust separator, the dust inside the steam falls down and goes out through the discharging hole of the cyclone dust separator. The steam goes into atmosphere directly through the chimney which is connected to the cyclone dust separator.

>>> Output Belt Conveyor takes the dried sand out of the dryer accordingly.

>>> Electric Control Cabinet is used to control the whole silica sand drying system.