Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

According to the clients' need, Sunco Machinery can design and supply the drying sand machine with different capacity, and the drying capacity varies from 1 ton per hour to 50 tons per hour or as need.

Drying Sand Machine in the market is mainly rotary sand dryer which is named as "work horse". It has the advantanges of simple structure, durable, stable work performance, high sand drying capacity, etc.

Drying Sand Machine is usually called as sand dryers, silica sand drying machine, slag dryer, etc. It is ideal for drying mineral material such as river sand, silica sand, slag, fly ash, etc.

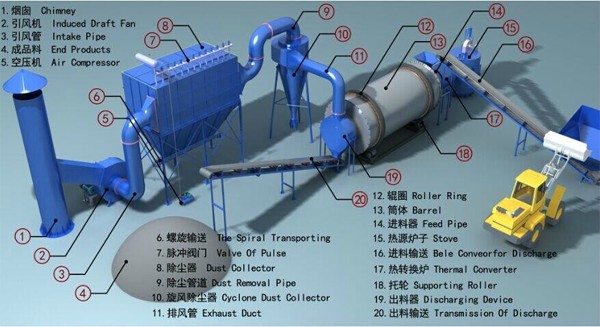

Drying Sand Machine consists of round drum, gear, ring, carrier roller, air pipe, high pressure draught fan, reducer machine, chimney, cyclone dust catcher, 40mm thickness heat insulating layer, feeder, electric control box, belt conveyor, etc.

Drying Silica Sand Machine Technical Data:

Model | Processing Capacity | Input Moisture | Output Moisture | Main Motor for Sand Dryer | Coal Calorific Value | Feedinlet Temperature |

Ø1.5X14M | 10-12 | 17-23% | <10% | 15 | >5500 KCAL/KG | 700±50℃ |

Ø1.8X14M | 15-18 | 17-23% | <10% | 18.5 | >5500 KCAL/KG | 700±50℃ |

Ø2.0X16M | 20-25 | 17-23% | <10% | 18.5 | >5500 KCAL/KG | 700±50℃ |

Ø2.2X18M | 25-30 | 17-23% | <10% | 22 | >5500 KCAL/KG | 700±50℃ |

Necessary Information needed for design the drying sand machine:

>>> Input Moisture Content (%) of the wet sand ?

>>> Output Moisture Content (%) of the dried sand needed ?

>>> Input Capacity (ton per hour) of the silica sand dryer machine ?

>>> Prefered fuel such as coal, wood, diesel, or natural gas, etc ?