Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

As the sawdust is coarse powder, what is more, for the rotary sawdust dryer, it is to use high temperature flue gas to heat and dry the wet sawdust, then how to get rid of the dust from sawdust drying system ?

In the sawdust drying system, some dust will be generated. In the industrial area of the developed countries, there are very strict policy on the dust pollution. For example, in South Africa, the local government ask that the dust emission should not greater than 250mg/m3.

Then how to get rid of the dust as much as possible?

Usually there are the following several methods for the dust removal of sawdust drying system:

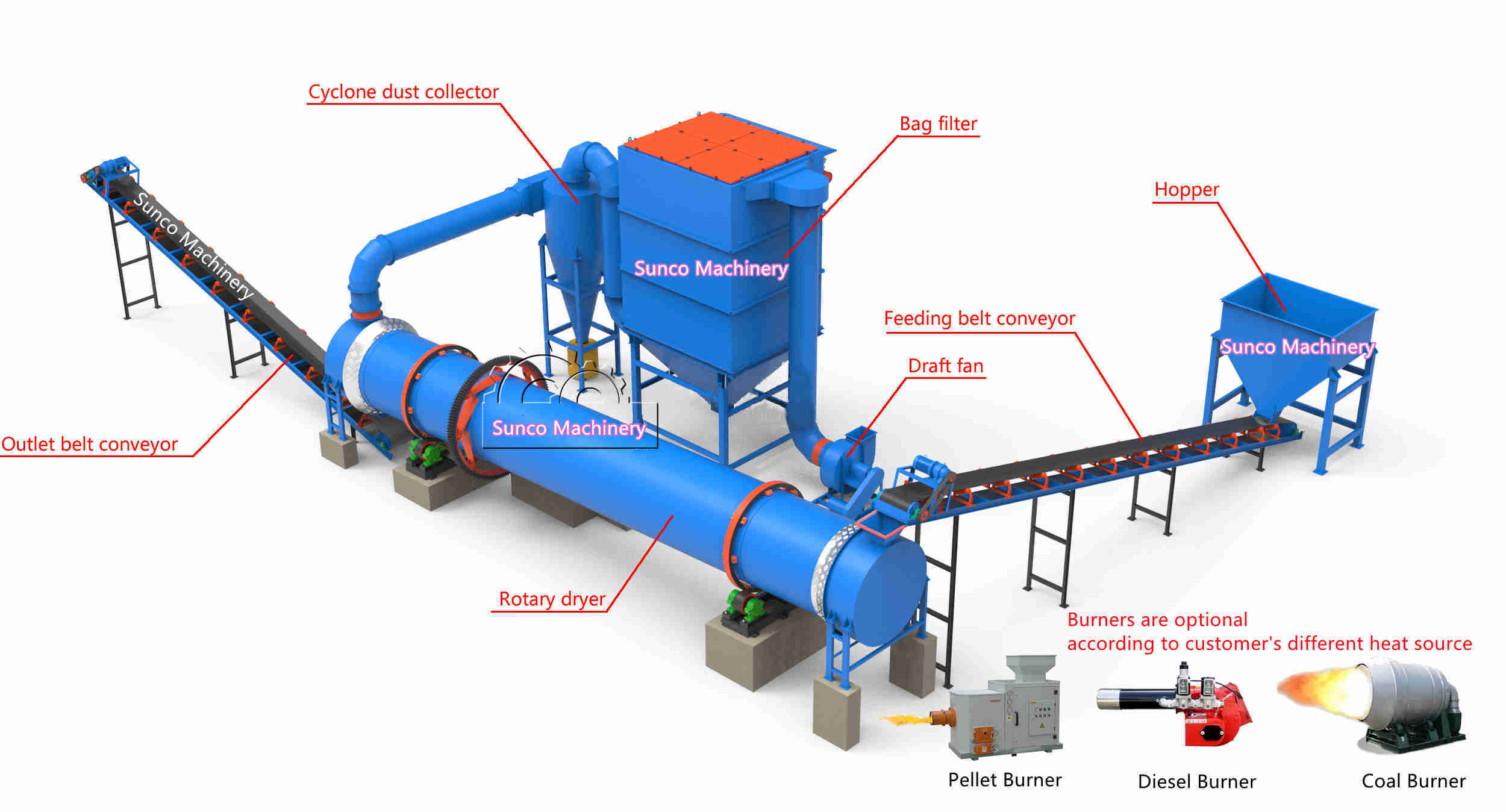

>>> To use several sets of cyclone separators to collect the fine dust from the exhaust air as much as possible.

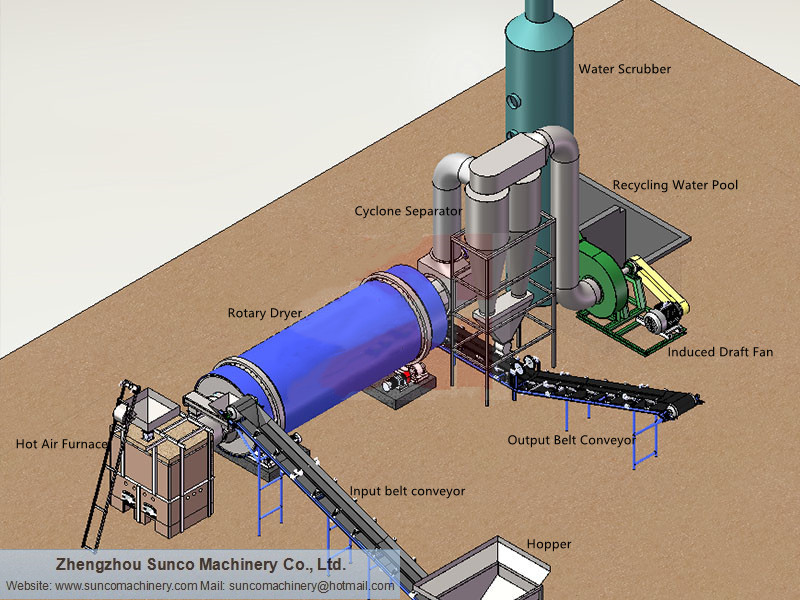

>>> To use water scrubber to collect the fine dust.

>>> To use Pulse Bag Filter to collec the fine dust.

To use cyclone dust separator to collect the fine dust from the exhaust air, it is the most economical way, but some very fine powder can not be collected. The collected fine wood powder also can be used as final product.

To use Water scrubber to collect the fine dust from the exhaust air, it is economical, but the collected fine powder will get wet, then need to dry it again for future use.

To use Pulse bag filter to collect the fine dust from the exhaust air, the dust emission can be less than 50 mg/m3. Although it is more expensive, but it can treat and process the dust problems successfully, and protect the environment.

For detailed information of sawdust drying system, please feel free to contact Sunco Machinery:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261