Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Silica sand dryer is a new type drying equipment developed by Sunco Machinery, which has the characteristics of reliable operation, large drying capacity, high work efficiency, and low energy consumption. When the initial moisture content of quartz sand up to about 20-30%, the final moisture content of sand can be dried below 1%, which greatly meets the needs of large sand manufacturers while saving production costs and improving economic benefits.

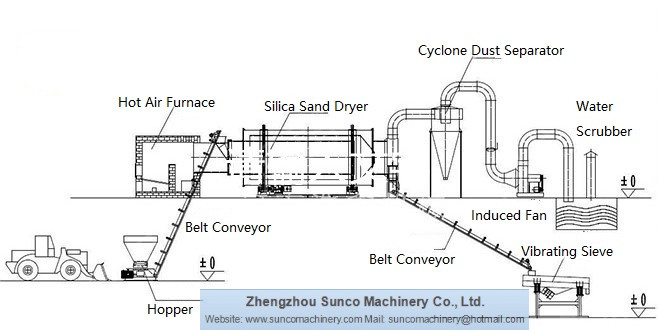

Work Flow of Silica Sand Drying System:

>>> Tractor shovel feeds wet silica sand into hopper.

>>> The silica sand is firstly evenly fed onto the belt conveyor through a disc feeder, and then enters the rotary sand dryer machine through a inlet pipe. The heat generated by the combustion of the fuel in the hot air stove enters the main machine under the action of the exhaust fan to contact the sand, completing the heat transfer and quickly evaporating water.

>>> The silica sand dryer produced by Sunco Machinery has a three way sealed structure, which can effectively reduce heat loss and improve thermal efficiency. The dried silica sand is transported to a linear vibrating screen for screening, and then sent to a storage tank by a hoist for storage or packaging and bagging. The upper part of the receiving hopper is used to discharge dust and other pollutants from the process flow.

>>> After being treated by the dust removal system, it can effectively achieve the goal of environmental protection.

Sunco Machinery can design the related silica sand dryer system according to your actual need, and the sand drying capacity can be up to 60 tons per hour.

For the detailed offer of New Type Silica Sand Drying Machine, please feel free to contact Sunco Machinery:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261