Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Rotary drum type slag dryer is widely used in the fields of building materials, metallurgy, beneficiation, chemical industry, cement and so on, to process and dry materials such as ore slag, carbide slag, limestone, clay, river sand, quartz sand and granulating slag.

Slag drum dryer can be equipped with various combustion furnaces including fluidized bed furnace, coal dusting furnace and coal furnace. As a kind of rotary dryer, it consists mainly of rotary drum, air induction devices, high speed thrashing devices, winnowing plates, auto-cleaning devices, actuating devices, conveying system, blast heaters, reducers, support and sealing systems.

The complete slag drying plant is with features of elegant design, perfect workmanship, stable performance, advanced technology, high yield, low energy consumption, small scale floor space and high level of mechanization.

Working Principles of Rotary Drum Type Slag Dryer Machine:

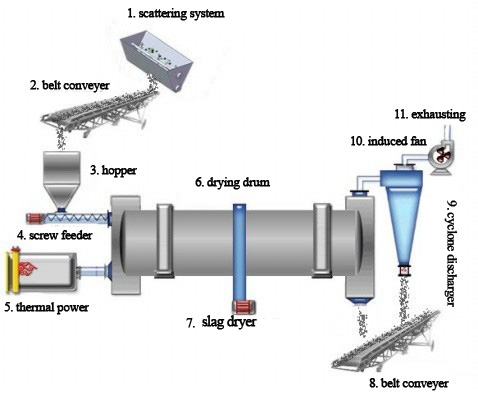

>>> Through belt conveyer or bucket elevator to the hopper, the material will then be transported to the feed inlet via feeding pipes.

>>> Technically, the slant angle of the feeding pipe shall be larger than the material dip angle so as to the material can smoothly flow into the slag dryer.

>>> Within the slag drying drum, a horizontally oblique rotary cylinder, feedstock flowing into from the higher end of it will reversely contact with the heat-carrying agent from the lower end. There is also the design of concurrent flow of material and the agent flowing into the drum.

>>> The material slag will by gravity flow to the lower end while the drum is spinning. Going headway, the moist material will be dried either directly or indirectly by hot air and finally carried by the conveyer to the outlet.

>>> The shoveling plates upon the internal wall are for spreading material to the hot air so that the drying speed and efficiency can both be stepped up. Generally, the heat-carrying agent includes hot air, flue gas and the like.

>>> After drying work, material slag carried by the agent shall be separated through cyclone. For reducing dust content of the tail gas, bag type dust collector or hydrofilter shall be applied into use.

For the detailed offer of Rotary Slag Dryer Machine, please feel free to contact Sunco Machinery:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261