Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

What is the working principle of Slag Drying Machine ?

Slag dryer machine also is called slag dryer, slag drying machine, rotary slag dryer, etc, and it can be used for drying minerial material such as slag, river sand, frace sand, silica sand, fly ash, garnet sand, etc. For such minerial material, they have the similar fatures of: with surface water, heavy, and can bear high temperature drying, etc.

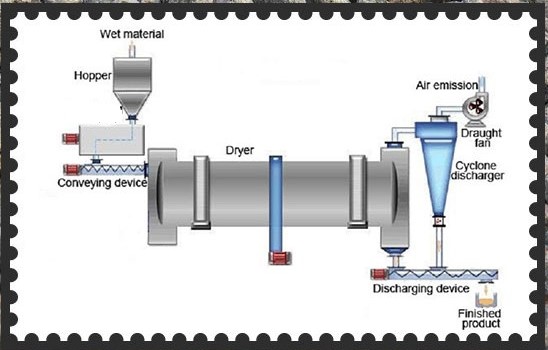

The wet raw slag is sent into the mechanical feeding hopper by tractor shovel, then the following input belt conveyor sends wet slag into rotary slag dryer machine. Slag dryer cylinder is a rotating cylinder with a slight incline to the horizontal line, and the flow ability of slag inside the dryer drum is good.

Burner and hot air furnace creat the high temperature air for the slag drying system.

Under the action of induced fan, the high temperature air is sucked into the slag dryer machine.

Inside the slag dryer, there are many welded lifting plates. In the slag drying process, the dryer drum is rotating, and these lifting plates shovel up and down the wet slag, during this process, the hot air contact and heat the wet slag, then the slag temperature rise quickly, then the water is evaporated into vapor gradually, then under the action of induced fan, the vapor is sucked out of the slag dryer in time.

Under the action of lifting plates, the slag is pushed to the outlet end of the dryer from the inlet end, and finally goes out of slag dryer.

There is frequency conversion motor for the slag dryer machine. By adjusting the rotation speed of the frequency conversion motor, then can increase or reduce the slag dryer's rotation speed, then the slag takes longer or shorter time to pass through the slag dryer drum.

In other words, by adjusting the rotation speed of frequency conversion motor, we can increase or reduce the slag drying time accordingly. If want to have lower output moisture content, then can have longer drying time; if water to have higher output moisture content, then can have shorter drying time.

Finally the dried slag is taken away by output belt conveyor to the storage area for next step production such as classification, packing, etc.

For detailed offer of Rotary Slag Dryer Machine, you are welcome to contact Sunco Machinery:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261