Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

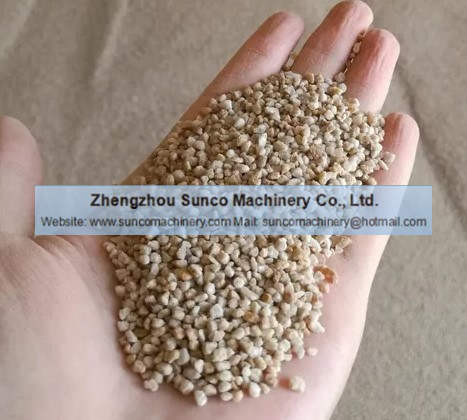

Silica Sand, also is called quartz sand, silica stone, it is widely used in Sand blasting for rust removal. Then what is the requirements on the technical standard of blasting silica sand ?

'

Silica sand is generally used for rust removal and anti-corrosion construction, 10-20 mesh quartz sand and 20-40 mesh quartz sand, with uniform particle size, which will not block the nozzle mouth of sand blasting machine, and can ensure the construction progress. The amount of quartz sand per square meter used for tank surface rust removal and steel structure surface rust removal is basically the same.

Since the hardness of quartz sand can reach Mohs 7, it is very hard and wear-resistant, and the price is relatively low, so it can be used as sand blasting material through high-pressure air pump. The quartz sand used for sand blasting and rust removal shall meet the following key technical requirements, including:

>>> Chemical indicators:

1. Silicon dioxide greater than 99%;

2. Fe2O3 less than 1%;

>>> Physical indicators:

1. Particle requirements: 4-8mm, 8-16mm, 16-32mm;

2. The mud content should be less than 1%, and ultrafine particles with a particle size of 140 or finer should be less than 5%;

>>> Moisture content requirement:

1. not exceeding 3%

After being used, the silica sand will become dirty with much rust powder. Before to use the silica sand again, need to wash and clean it, then dry the wet clean silica sand by Silica Sand Dryer Machine, and reduce its moisture content to be less than 3%.

After being washed, the moisture content of silica sand is up to about 20-25%, and it is too wet to be used again for sand blasting.

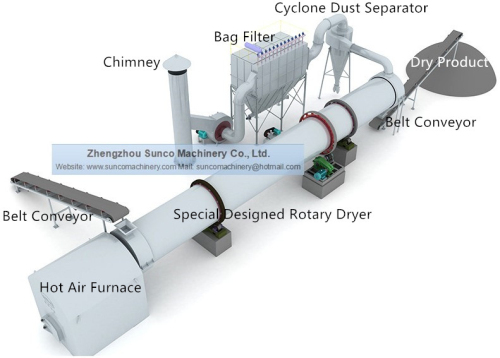

Sunco Machinery Silica Sand Dryer Machine is ideal for drying wet Material grind silica stone, and quickly can reduce its moisture content to be less than 3% or even bone dry. It is adopts high temperature hot air drying methods, and the temperature of hot air is up to about 400 centigrades.

Inside the Silica Sand Dryers, the wet sand is heated by high temperature air sufficiently, then the sand temperature rises quickly, then the water become vapor and to be got rid of. Under the action of induced fan, the water vapor is sucked out of the silica sand drier in time, and the dry silica sand leaves the dryer machine through the outlet.

For one set of silica sand drying machine, enough heat is one very important factor. It needs to burn the fuel to generate the hot air for the sand drying process. The clients can select the related most economical fuels such as coal, chop wood, waste wood, natural gas, diesel, etc according to their local market. Accordingly, Sunco Machinery can design and supply the related hot air furnace for you specially.

For detailed offer of Silica Sand Drying Machine, please feel free to contact Sunco Machinery:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261