Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

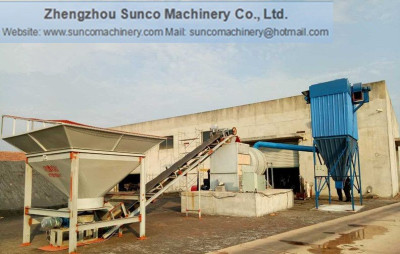

Silica Sand Dryer Equipments mainly includes belt conveyor, silica sand dryer, burner, hot air furnace, dust catcher, induced fan, cyclone separator, vibrating sieve, bagging machine, etc, and the key equipment is silica sand dryer.

The working principle of Silica Sand Dryer Machine: Burner and hot air furnace burn the fuel to creat high temperature air for the sand drying system, and the special inner lifting boards and guide plates shovels the wet sand up and down so that it can be heated by hot air sufficently, and with high heat exchanging efficiency. When the wet sand is heated and its temperature rises quickly, then the water is evaporated into vapor, and to be sucked out of the sand dryer by the induced fan, finally the dried quartz sand leaves the sand dryer's cylinder, and to be taken away by the belt conveyor.

Workflow of Silica sand drying system is as follows:

Forklift--> Wet Silica Sand --> Hopper --> Round Feeder --> belt conveyor --> sand dryer --> belt conveyor-->vibrating screen.

Hot air furnace supply the hot air for the sand dryer.

For the sand dryer system, to choose one suitable hot air furnace is very important. In the market, some hot air furnace still adopts old technology, and the heat efficiency is very low. Before drying, many heat has already been lost. It is really a big waste of the fuel.

Sunco Machinery design one new type hot air furnace which is suitable for coal, waste wood, natural gas, diesel,etc. This new type hot air furnace heat efficiency can be more than 95%. What is more, it is produced well at the seller's factory. Thus it will save much money and time for the users.

For more details of Silica Sand Dryer Equipments, please email to : suncomachinery@hotmail.com or contact us by Mobile/WhatsApp: +86-15838214261.