Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Sunco Machinery can specially design and manufacture Rotary sand dryer Machine for drying garnet sand with different drying capacity. After being dried by the Garnet sand dryer, the moisture content of the garnet sand can be less than 0.5-1% or even bone dry. The the users can use vibrating screen to classify the garnet sand into different size ranges as need.

Application of Garnet Sand:

Due to its high hardness and good chemical properties, garnet is widely used in industrial production. The quality requirements of garnet sand mainly include hardness, purity, and particle size, and the quality requirements vary depending on the use. For special purposes, there are also requirements for the particle size composition of the product, but there is no unified regulation, mainly agreed upon by the supply and demand parties. The use of garnet can be divided into abrasive garnet and non abrasive garnet.

(1) Sand blasting and rust removal of steel structures, hulls, bridges, etc;

(2) Water knife cutting of metal, stone, glass, etc;

(3) Filter media for chemical, petroleum, pharmaceutical, and water treatment;

(4) Grinding of materials such as marble, optical lenses, glassware, leather, etc;

(5) Grinding wheel, oilstone, sandcloth, sandpaper raw materials;

(6) Wear resistant materials such as expressway pavement, runway, wear-resistant rubber, anti-skid paint, etc;

(7) Widely used in the construction industry, high-end real stone paint is used for exterior wall decoration and indoor decoration, with a noble and elegant temperament. Ideal new non-metallic wear-resistant floor aggregate.

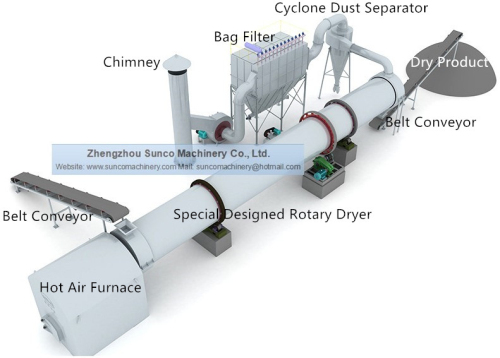

Ratary Sand Dryer Machine for drying garnet sand is use high temperature hot air to heat and dry the wet garnet sand quickly and continuously, and get rid of the water from the garnet sand. The Rotary sand dryer also is called garnet sand dryer, silica sand dryer, sand drying machine, etc.

There is Hot air furnace and burner to creat the high temperature air by burning the fuel for the sand drying system. When the fuel is solid fuel such as coal, waste wood, we will use coal and wood fired hot air furnace; When the fuel is liquid fuel such as natural gas, diesel, we will use burner working together with the special hot air furnace.

During the garnet sand drying process, the wet sand can move in the same direction or opposite direction with the hot air. When the moisture of the sand is not big, then we can make the wet sand moves in the same direction with the hot air. Thus it will have higher heat exchange efficiency, but the disadvantage is that the dry sand goes out through the high temperature end of the sand dryer, the dry sand would be very hot, and people can not load the sand into bag directly.

The work flow of garnet sand drying line is as follows:

For more information of Rotary Silica Sand Dryer for drying garnet sand, please feel free to contact Sunco Machinery by:

Email: suncomachinery@hotmail.com

Mobile/WhatsApp: +86-15838214261