Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Sunco Machinery is one professional Slag Drying Plant Manufacturer, and the key equipment slag dryer machine is to adopt high temperature hot flue gas drying methods, and within about 20 minuteds, the moisture content of wet mineral slag can be reduced to be less than 3%.

Sunco Machinery can design and customize the Slag Drying Plant according to the needed drying capacity and final output moisture content of dried slag as demand as follows:

>>> Initial moisture content (%) of wet slag ?

>>> Output moisture content (%) of the dried slag needed?

>>> Input capacity (ton per hour) of the rotary slag dryer ?

>>> Prefered fuel such as coal, diesel, or natural gas, etc ?

Then, what is the workflow of Slag Drying Plant ?

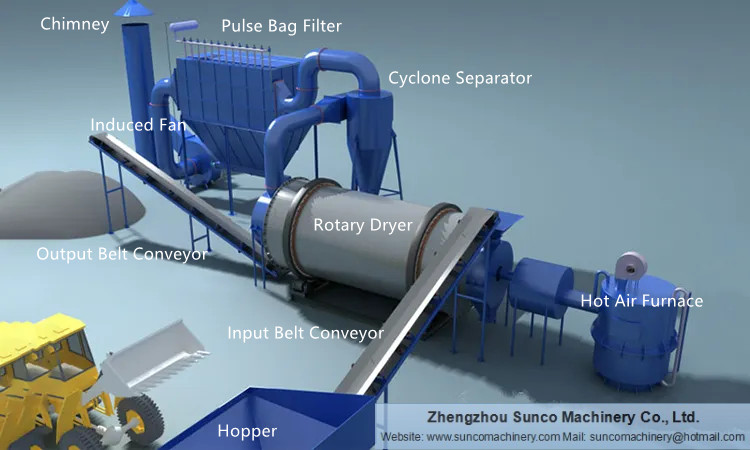

>>> Burner and Hot Air Furnace supply the high temperature air for the slag drying plant.

>>> Tractor shovel feeds wet slag into mechanical feeding hopper.

>>> Input Belt Conveyor and inlet feeder sends the wet slag into the slag rotary dryer.

>>> Rotary Slag Drying Machine stir and make the wet slag contact with the high temperature air sufficiently, and the water is evaporated into water vapor quickly. After the drying process, when the slag leaves the slag dryer, the moisture content of slag is less than 3% or as need.

>>> High pressure draft fan sucks the high temperature air into the slag dryer, and makes the exhaust air mixed with water vapor out of the rotary slag dryer.

>>> Cyclone Dust Separator separate the dust from the exhaust air and water vapor.

>>> Pulse bag filter or water scrubber is used to collect the fine dust.

>>> Output Belt Conveyor takes the dried slag out of the slag drum dryer, and send it into storage area.

>>> Electric Control Panel is used to control all the above machines in the slag drying plant.

For detaild offer of slag drying plant, please feel free to conact Sunco Machinery by:

>>> Email: suncomachinery@hotmail.com

>>> Mobile/WhatsApp: +86-15838214261

>>> Video: https://www.youtube.com/watch?v=yGzcIJ0aFL0