Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Flash sawdust dryer machine also is called airflow sawdust drying machine,pipe type sawdust dryer machine, and it is for small capacity sawdust drying system less than 600kg per hour.

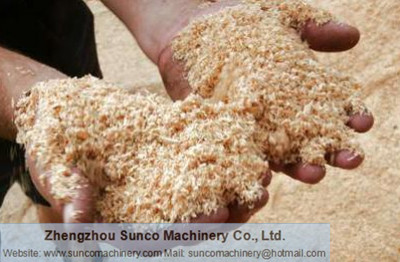

The sawdust dryer is specially designed for drying the biomass materials, such as wood sawdust, small wood chips, rice hull, sunflower husk, peanut shells, etc. Depending on the different drying principles, sawdust dryers are classified into two types, sawdust flash dryers, and rotary drum sawdust dryers. In this article we mainly focus on the flash sawdust dryer machine.

Why the flash sawdust dryer is needed ?

As the ideal water content of sawdust is 8%-15% for producing biomass briquettes and pellets. Usually, the moisture of the untreated wet sawdust is 30%-50%, and fresh sawdust from the sawmill can even up to about 60%. Even if these materials are air-dried enough, the water content can be reduced to 20% at the most, but they still can not meet the requirement for producing briquettes. So it is necessary to use the flash sawdust dryer to heat and dry the wet sawdust before making sawdust briquettes.

Sawdust Flash Dryer Introduction:

Sawdust flash dryer includes heating stove, pipes, fan, and cyclone. It is also called airflow dryer or pipe dryer. Wet sawdust enters the airflow dryer through the feeding hopper, they are mixed with the hot air by the airflow force of the electric fan. Sawdust flows through the curved pipes and finally enters the cyclone. At last, water vapor of sawdust is taken out by the hot air and expelled out from the up outlet of the cyclone, and sawdust is discharged from the down outlet.

Features of biomass flash sawdust dryer machine:

Biomass materials range and size: rice husk, wood sawdust, wood shavings, crushed tree branches, small wood chips, etc. Diameter is less than 3mm, length is less than 5mm.

Thermal efficiency: Because the material is highly dispersed in the air flow, the contact area between the material and hot air is large, so the drying time is short, the processing capacity is large, and the thermal efficiency is high. When drying unbound water, the thermal efficiency can reach 60%.

Fuel for heating: waste wood, coal, steam and electric heating.

Installation space is small: The hot airflow dryer is pipe structure, it can be installed in line and also can be fold installation to save the space.

Airflow Sawdust Drying Machine Technical parameters:

| Model | Capacity | Power | Dimension | Weight |

| ASD220 | 300-400 kg/hour | 4kw | 2.25x1.1x1.3m 1.45x0.85x1.48m | 980kg |

| ASD320 | 400-600 kg/hour | 7.5kw | 2.40x1.8x2.0m 1.5x1.45x1.4m | 1480kg |