Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Rotary Sand Drier Machine by Sunco Machinery is ideal for drying mineral material such as river sand, silica sand, quartz sand, frac sand, slag, etc, and it also have the popular name of silica sand dryer, sand drying machine, etc.

Rotary sand drier machine mainframe consists of large drum with inner welded lifting plates, inlet cover, outlet cover, frequency conersion motor, reduction gear box, large steel frame, carrier rollers, large gear, air duct, etc.

Usually have two types of rotary sand drier: Single Pass sand dryer and Triple Pass Sand Dryer. Of course, triple pass rotary sand dryeir with better heat efficiency and higher output capacity, and the related land occuptation area is less. Its detailed advantages is as follows:

>>>New type triple pass rotary drum dryer, three drum connect with each other, and realize self-insulation layer ;

>>>Inner temperature is 300-400℃, discharging temperature <= 75 ℃, can send into storage room directly, and no need cool device;

>>> Made of wear resistant manganese plate, 3 to 4 times more hardwearing than ordinary steel plate ;

>>> 1/3 of the single drum dryer's coal consumption, power saving 40%, standard coal consumption per ton dried sand < 16 kg.

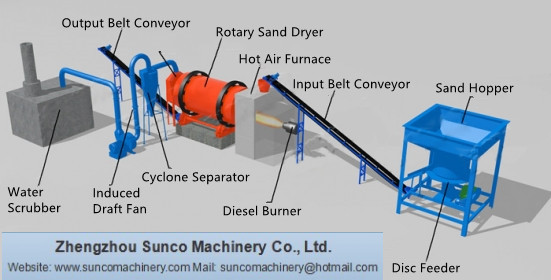

Rotary Silica Sand Drier system layout drawing usually is as follows:

>>> Tractor Shovel feeds wet silica sand into sand hopper;

>>> Input Belt Conveyor feeds wet silica sand into rotary sand drier machine;

>>> Output belt conveyor takes away dried silica sand from the silica sand dryer;

>>> Induced fan makes the hot flue gas into the sand dryer machine, and after the drying process, makes the exhaust air and vapor out of the dryer drum in time;

>>> Cyclone dust separator collects the fine dust, and protect the clean of the work site;

>>> Water scrubber is to get rid of the fine dust from the exhaut air.

For more information of rotary silica sand drier machine, please feel free to contact Sunco Machinery.