Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

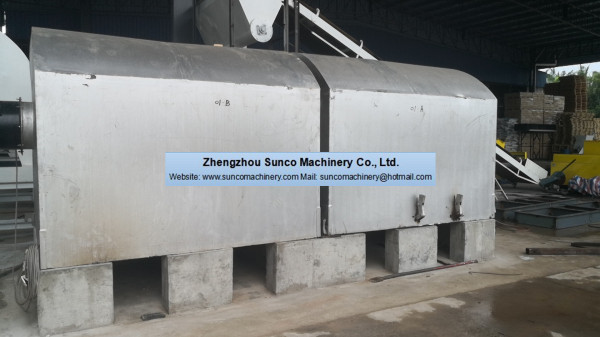

Wood shavings production line mainly consist of log shavers, rotary wood shavings dryers, burner, hot air furnace, rotary drum sieve, etc. Sunco Machinery has been devoted to the research and production of wood shavings dryer since the year 2001.

Wood Shavings dryer system workflow is as follows: Logs --> Log Shavers --> Wet Wood Shavings --> Rotary Wood Shavings Dryer --> Cyclone Separator --> Rotary Drum Screen --> Dry Wood Shavings ---> bale machine ---> Final product.

For the wood shavings dryer machine, it is to use high temperature air to heat and dry the wet material quickly. Thus need to burn fuel to generate the heat for the drying process. Usually the fuel can be waste wood, coal, diesel, natural gas, etc.

For the owner of wood shavings plant, usually there is much waste wood. Thus you will not need to purchase diesel, or natural gas, etc with much expensive price, and directly use waste wood as fuel. What is more, after being screened by the rotary drum screen, the small wood particles can be used as fuel also.

For the wood shavings drying machine's operation cost, except the electricity consumption, the fuel consumption cost occupy much more percent. By using waste wood as fuel, can help to save much fuel cost accordingly, to ensure to have more economic benefit.

If to use waste wood as fuel, when the waste wood is burning, it will occure some sparks, and maybe sucked into the wood shavings dryer, and contact the shavings, then might cause fire if meantime the wood shavings is stuck inside the dryer and can not pass through the cylinder of wood shavings drier smoothly.

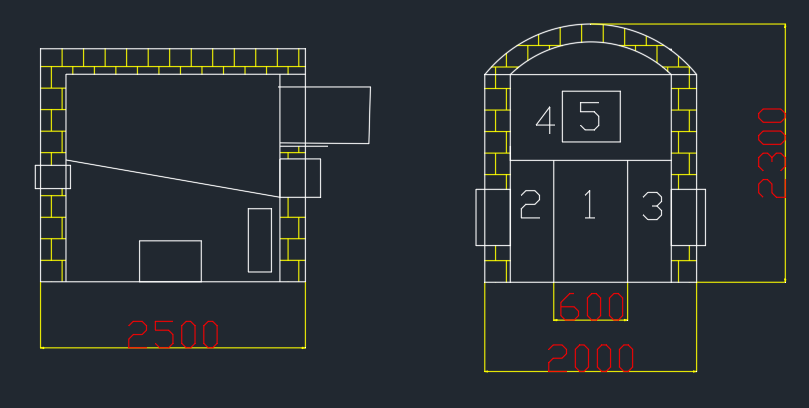

Considering the possible fire issues, Sunco Machinery specially designed one new type waste wood fired hot air furnace. It consists of waste wood burning chamber and the fireproof & air distribution chamber.

The burning chamer is mainly to burn the waste wood, and after that under the action of induced draft fan, the hot flue gas goes into the fireproof & air distribution chamber.

The fire flame goes #1 chamber, then goes into #2 and #3 chamber with inlet hole for ambient air, after that the hot air goes into #4 Chamber, finally come out from #5 outlet, and then the hot air goes into the dryer machine.

The moving distance inside the fireproof & air distribution chamber is up to about 7.5m totally, it means that the fire flame surely can not contact the wood shavings directly, and only the hot air goes into the dryer to contact and heat wet wood shavings.

For more information of waste wood fired hot air furnace of rotary wood shavings dryer, please feel free to contact Sunco Machinery at your convenience.