Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Rotary sawdust dryer machine is important and indispensable drying equipment in the process of production mechanism charcoal. The materials of the timber which have been crushed can be produced to the fashioned mechanism stick through the sawdust dryer and the rod making machine. Then the fashioned mechanism sticks are made into the mechanism charcoal by the coking furnace.

The dry sawdust also is widely used for the production of compressed board, and also can be used as animal bedding materials.

Inner Sctructure of Rotary Sawdust Dryer:

Rotary sawdust dryer system mainly mainly consist of hot air furnace, feeder, air duct tube, cyclone dust separator, the induced draft fan, rotary dryer, chimney, electric control box, etc.

there is hot air furnace used to burn the fuel, and creat high temperature air for the sawdust drying process. Under the action of induced draft fan, the high temperature air is sucked into the sawdust dryers, and the temperature of dryer cyclinder increase quickly.

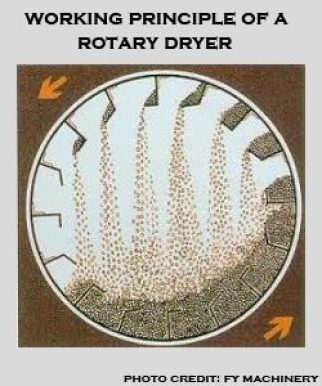

In the cylinder of rotary sawdust dryer, there are many welded lifting plates with certain height and slopes. When the sawdust dryer is rotating, the wet sawdust will be shoveled up and down, moves to the outlet end of the dryers. The high temperature air pass through these sawdust, meantime the hot body of dryer also contact the wet sawdust. Thus, the wet sawdust absorb the heat, and its temperature rises quickly, when the temperature is rising, the water in the wood powder gradually become vapor, and to be sucked out by the induced draft fam, and finally get the dry sawdsut with the tarked moisture content such as about 13-15% which is very suitable for the production of wood pellets, etc.

For the rotary sawdust dryer, the cheaper fuel with stable heat calorific value is very necessary. The fuel choice usually can be waste wood, diesel, natural gas, wood pellets, etc, and the clients can select the most suitable fuel according to the actual situation.