Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Chicken manure dryer machine by Sunco Machinery not only can help to get rid of the water from the wet manure, but also can solve the manure odor smell problems.

Chicken manure dryer machine is by using high temperature quick continuous drying method to heat and dry the wet manure diectly within a short time, and it is suitable for assemly line production.

Chicken manure dryer machine also is well kown as poultry manure dryer, rotary manure dryer, manure drying machine, etc, and it is mature product which is developed and optimized on the base of rotary drum dryer.

Odorless Chicken Manure Drying Machine of Sunco Machinery has advantages of compact structure, high heat efficiency, low energy consumption, easy operation and maintenance, long durable, high drying capacity, etc.

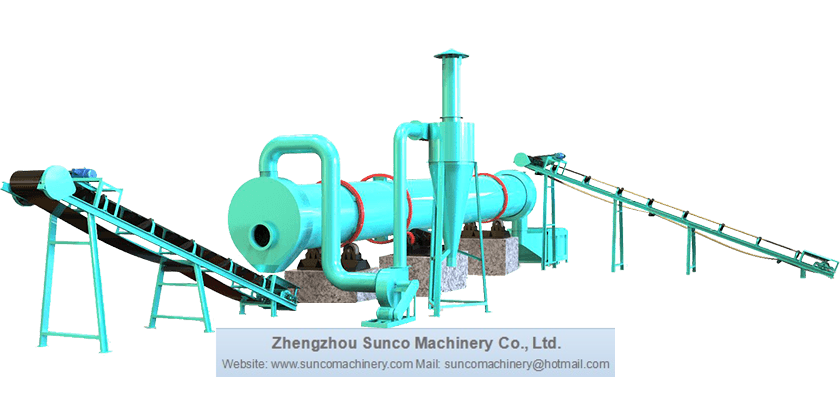

Odorless Chicken Manure Dryer machine consists of burner, hot air furnace, feeding device, discharging device, rotary cylinder, lifting boards, driving device, supporting device, induced draft fan, motor and reducer, chimney, air duct tube, electric control panel, etc.

The workflow of Odorless Poultry Manure Drying machine is as follows:

>>> Hot Air Furnace is to generate and supply the high temperature air for the Odorless chicken manure drying machine.

>>> Tractor Shovel put the wet chicken manure into Mechanical Feeding Hopper.

>>> Mechanical Feeding Hopper sends the wet chicken manure into inlet screw conveyor.

>>> Inlet Screw Conveyor sends the wet chicken manure into the Special Designed Rotary Dryer.

>>> Inside the manure dryer machine, the wet chicken manure is heated and dried by high temperature air sufficiently, and the moisture content of the chicken manure is reduced to be about 15% or as need.

>>> Draft fan is used to make high temperature air into manure drying machine, after heat exchanging process in the dryer, makes water vapor and exhaust air out of the chicken manure dryer cylinder, and then goes into cyclone dust separator.

>>> After being dried, wet chicken manure become dry manure, most of dry chicken manure come out from the outlet of the chicken manure dryer machine, and some fine chicken manure powder is mixed with the exhaust air, and then goes into cyclone separator. Cyclone separator is used to separate the dry chicken manure powder from water vapor and exhaust air. Finally the water vapor and exhaust air come out from the top of cyclone separator, and then goes into deodorization tower; the fine dry chicken manure powder falls down to the bottom of cyclone separator, and come out through wind closing device.

>>> Belt Conveyor takes the dry chicken manure away from the chicken manure dryer machine, and send it into pellet mill.

>>> Pellet Mill makes the chicken manure into pellets.

>>> Belt Conveyor takes away the chicken manure pellets from the pellet mill.

>>> Deodorization Tower and Condenser are mainly used to get rid of the strong smell inside the exhaust air, and finally the water vapor become water, and the exhaust air goes into atmosphere through chimney.

>>> Electric Control Cabinet is used to control all the machines in the poultry manure drying machine.