Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

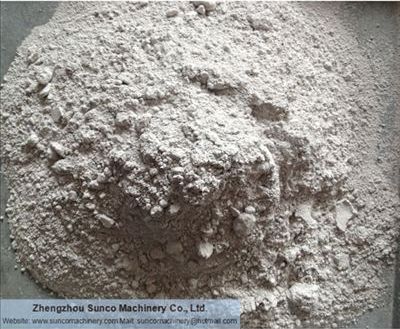

Slag is a by-product in the ironmaking process of blast furnace. In the process of iron making, iron oxide is reduced to metallic iron at high temperature, and impurities such as silica and alumina in iron ore react with lime to form molten substances with silicate and aluminosilicate as the main components, which are quenched and cooled into loose and porous particles, namely blast furnace slag, or slag for short.

In industrial production, slag plays an important role, especially in some major factories. The slag is refined and processed into slag cement, slag powder, slag powder, slag Portland cement, slag cotton, blast furnace slag, granulated blast furnace slag powder, copper slag, slag vertical mill. It saves energy consumption. However, slag pollutes the air to a certain extent. People who have worked in the mine for many years are prone to respiratory diseases caused by slag.

The raw slag from blase furnace usually is wet with moisture content up to about 20%, before using it to produce cement, firstly need to reduce its moisture content to be less than 3% by using rotary slag dryer, and get the dry slag.

What is more, some wet slag is in lump type, and before drying, have to use crusher machine to reduce its size, and crush it into smaller particle size in advance.

Blast furnace slag has been used for many years as a supplementary cementitious material in Portland cement concrete, either as a mineral admixture or as a component of blended cement.

The use of Blast furnace slag as a partial Portland cement replacement takes advantage of the energy invested in the slag making process and its corresponding benefits with respect to the enhanced cementitious properties of the slag. Grinding slag for cement replacement requires only about 25 percent of the energy needed to manufacture Portland cement.

Moisture in blast furnace slag, which occurs in the granulation process or in pelletized slag, should be removed by drying prior to the use of Blast furnace slag as either an additive to Portland cement or a mineral admixture to Portland cement concrete.

Rotary Slag Dryer is the ideal drying machine for Blast furnace slag. Slag Dryer machine can dry the wet blast furnace slag with moisture content about 20% to be less than 3% or as need.

Slag drying line mainly consists of the rotating cylinder, high-speed breakup equipment, lifting plate, self-cleaning device, gear transimission device, hot air furnace, reducer machine, supporting device, sealing device, air duct system, dust cyclone separator,etc.

Sunco Machinery can design the needed capacity Slag Drying Machine System according to your need specially. If you are interested in the Slag Dryer, please do not hesitate to contact us by email: suncomachinery@hotmail.com or tel,/whatsapp: +86-15838214261 .