Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Sunco Machinery have devoted in the research and design of Alfalfa Dryer Machine since the year 2001, and we have the patent certificate from State Intellectual Property Office.

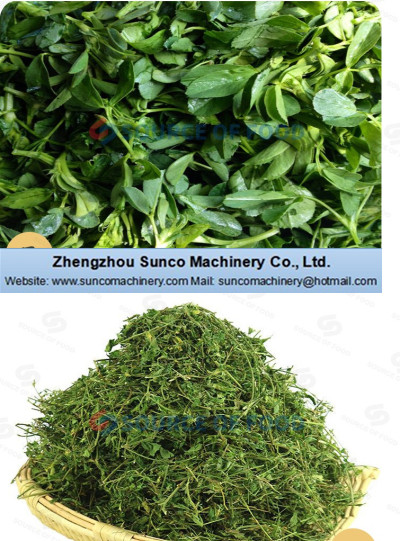

Alfalfa Dryer Machine by Sunco can dry the fresh cut alfalfa with moisture content 75%-80%, and after drying we can get moisture content less than 15% dried alfalfa which is safe for storage and packed into bags or bales, then suitable and easy for transportation by truck and ship.

Alfalfa Drying Machine by Sunco Machinery perfectly solve the nutrition damage problem by sunshine drying. After being dried by the alfalfa dryer machine, except the water is got rid of, the nutrition elements are saved, and the crude protein content is up to 20%-22%. What is more, the dried alfalfa is still in green color, and taste also is good for the animals.

Alfalfa drying machine system work flow is as follows:

>>> Hot Air Furnace consists of fuel burning chamber and Ash Collection Chamber. Hot Air Furnace is used to burn the dry waste wood and coal, and generate high temperature flue gas for the alfalfa dryer system.

>>> Gass chopper to pulversize the alfalfa into smaller size less than 10cm, so that it can be heated and dried with even speed.

>>> Input Belt Conveyor feeds wet alfalfa into rotary airlock valve.

>>> Rotary airlock valve has two functions:

(1) To send the wet alfalfa into dryer machine evenly;

(2) Avoid the cold ambient air into the dryer machine.

>>> Rotary Alfalfa Dryer Machine :

(1) To help high temperature flue gas to heat and dry the wet alfalfa sufficiently;

(2) The diameter and length of the dryer supply the enough drying chamber ;

(3) There is frequency converter motor for the dryer machine. By adjusting the rotation speed of the frequency converter motor to adjust the rotation speed of the dryer machine, then to reduce or increase the alfalfa drying time in the dryer machine according to the output moisture content.

>>> Induced Draft Fan:

(1) Make the ambient air into the hot air furnace, and supply Oxygen for the fuel burning process;

(2) Make the high temperature flue gas into the dryer machine to contact and heat the wet alfalfa sufficiently;

(3) Make the exhaust air and dry alfalfa out of the dryer cyclinder, and then goes into Cyclone Separator.

>>> Cyclone Separator:

(1) To separate the exhaust air from the dry alfalfa: The dry alfalfa comes out through the bottom of rotary airlock valve, and falls down

onto the bottom belt conveyor; the exhaust air comes out from the top of the cyclone separator, and goes through the induced draft fan, finally goes into atmosphere.

>>> Rotary airlock valve is installed on the bottom of cyclone separator:

(1) To send the dry alfalfa onto outlet belt conveyor evenly;

(2) To avoid the cold ambient air into the drying system.

>>> Belt Conveyor takes the dried alfalfa away from the alfalfa dryer machine, and send the dry alfalfa into product storage area for bagging.

Alfalfa Dryer, Alfalfa Drying Machine, Alfalfa Rotary Dryer, alfalfa drying plant

>>> Electric Control Panel is used to control all the machines of the alfalfa drying system.

For detail of Alfalfa Dryer Machine, please feel free to contact us :

--- Email: suncomachinery@hotmail.com

--- Tel./WhatsApp: +86-15838214261