Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

Input Capacity 1 t/h Fresh chicken manure dryer is designed for 100,000 birds scale layer farm which can generate about 10 tons fresh manure with moisture content about 75% per day.

For input capacity 1 ton per hour Fresh chicken manure dryer, when initial moisture content 75%,output moisture content 30%, , prefered fuel diesel, then output capacity is 360 kg/hour, water evaporation quantity is 640kg/hour, and every hour it needs to consume about 40kg diesel, and the electricity consumption is about 18kw.h per hour.

Input capacity 1 ton per hour Fresh chicken manure dryer system consists of the below equipments:

>>> Input screw conveyor with hopper, 220x3m, motor: 3kw: To feed wet manure into the chicken manure dryer.

>>> Diesel burner RL70, 1.1kw: To burn the diesel.

>>> Hot Air Furnace: To supply the diesel burning chamber.

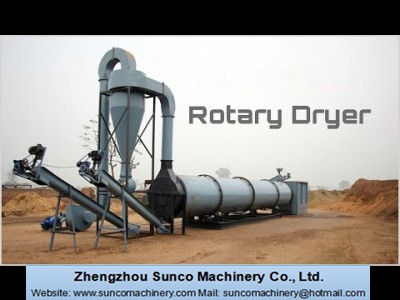

>>> Rotary chicken manure dryer, SC1012, motor 5.5kw: To supply the drying chamber and water evaporation space, also its specially designed inner structurer working together with hot flue gas to heat and dry the wet manure, evaporate and get rid of the water quickly.

>>> Cyclone Dust Separator: To separate the fine dust from exhaust air, reduce the dust pollution problems.

>>> Induced fan 7.5kw with air damper: To suck the hot flue gas into the manure dryer, and also make the exhaust air and water vapor out of the drier in time, then pass through the cyclone separator and induced fan, finally goes into atmosphere.

>>> Deodorization Tower 120 type with water pupm 2.2kw: Working together with recycling water pool, to collect the fine dust, and also help to lighten the smell.

>>> Output belt conveyor: To take the dried manure out of the chicken manure dryer, and send it to the product storage area.

>>> Electric Control Cabient: To be used to control the whole chicken manure dryer system.

The output moisture content of dried manure can be adjusted as need. If need more dry manure, then can increase the drying time; if need less dry manure, then can reduce the drying time. By increasing or reducing the dryer drum rotation speed, can reduce or increase the drying time accordingly.

For one successful chicken manure dryer, except the good quality drier itself, the cheapest fuel is also one key factor. As the fresh chicken manure is rather wet, it means that during the drying process, much water needs to evaporated into vapor to be got rid of, accordingly much heat is needed. If the clients can find and use the cheapest fuel, then the whole chicken manure dryer project will have better economical benefits.