Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

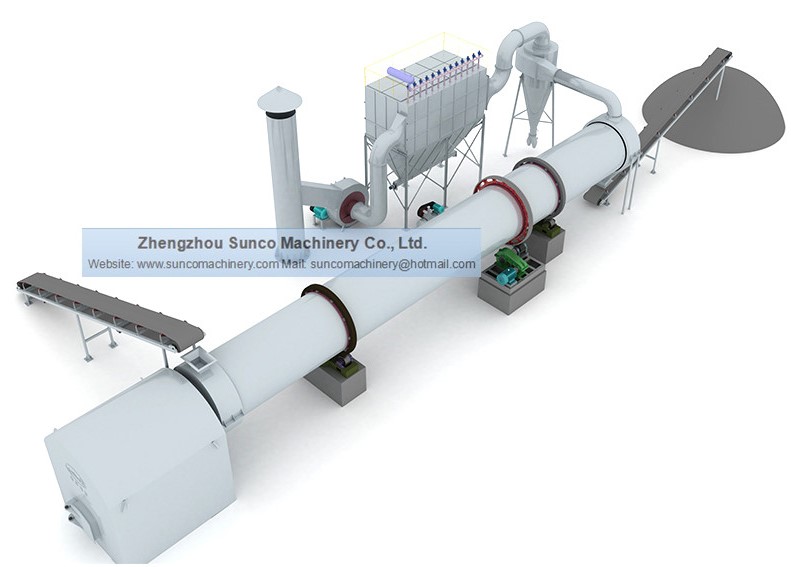

Rotary Silica Sand Dryer, also is called quartz sand dryer, which is popularly used for drying mineral material such as sand, slag, fly ash, etc. Just see from the name, we can know that it is developed from rotary drum dryer, and it is with the advantages of less invest cost, high production capacity, stable work performance, etc.

Rotary Silica Sand Dryer structure:

In the dryer there is lifting plate and multi-chamber device; on the surface of the dryer drum there is heat reservation layer; on the both end of the dryer drum there are inlet cover and outlet cover; on the dryer drum there is transmission gear. There are four sets carrier rollers work together with the Big Gear. There is one big supporting frame welded together with the dryer drum. The motor makes the gear box rotates, and the small gear of the gear box to use chain to make the big gear rotate, and then the dryer drum rotates. The rotation speed of the dryer drum can be adjusted by one speed adjusting device on the electric control panel.

Working principle of rotary silica sand dryer:

Heat Supplying System ---- Material Feeding System --- Drying System --- Dried Material Discharging System --- Water Vapor Exhaust System .

Under the action of draft fan, the ambient air goes into the heat exchanger, after heat exchanging, the hot air goes into the dryer. The hot air not only heat the wet material, but also heat the dryer drum body. Under the function of the lifting plate and special drum inner structure, the wet material moves up and down to the discharging end of the dryer drum in spiral route. During this process, the wet material not only absorb the heat of the hot dryer drum, but also have strong heat exchange with the dry hot air. During this process, the humidity inside the wet material is heated and evaporated into water vapor, and under the action of the induced fan, the dry material, the exhaust air with water vapor goes into cyclone separator, and then the dry material is separated out from the exhaust air and water vapor. After that, the exhaust air and water vapor come out from the top of the cyclone separator, and then pass through the draft fan, then goes into atmosphere. The dried material comes out from the outlet feeder(Rotary Airlock Valve) which is installed on the bottom of cyclone separator.

For one sucessful rotary silica sand dryer system, both of enough heat and high heat exchaging efficiency are key factors. The burner and hot air furnace is used to burn the fuel, and generate hot flue gas for the drying process. The clients can select the most economical fuel according to their local market, so as to save the fuel consumption cost as much as possible.