Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

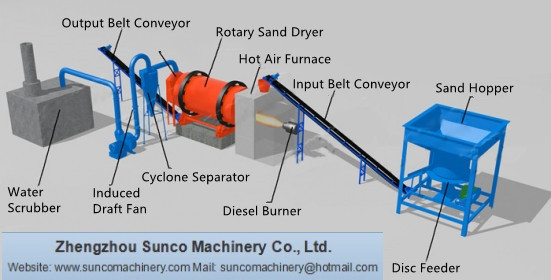

Burner and hot air furnace to burn the fuel, and generate high temperature air for the slag drying process.

The induced fan functions is: to suck the hot air into the dryer body, and suck out the exhaust air and vapor out of the dryers in time.

The wet slags are fed into the mechanical feeding hopper by dumper or tractor shovel, then a belt conveyor or bucket elevator send it into the slag dryer machine.

The slag dryer cylinder is a rotating cylinder with a slight incline to the horizontal line. The materials are sent out from the upper end and the heated airflow is sent out from the lower end. Both of them are mutually in contact with each other. With the rotation of the cylinder, the action of gravity will completely move some heated airflow with the materials into the end of the barrel.

Cyclone separator is to separate the fine dust from the exhasut air, and after that, the rest dust is caught by the bag filter.

In the advancement of the barrel, the wet materials directly or indirectly gain the heat of the airflow and get dried. Finally, the dried slag is discharged from the barrel and sent into the warehouse for further recycling.

The a successful slag dryer, the reasonable inner design of the cylinder is very important so that it can disperse the wet slag sufficently, then have more heat contact area between wet slag and hot air, thus to have higher heat exchanging efficiency, finally produce more dry slag with less energy consumption.

What is more, it is one whole slag drying system, in order to have good work performance and production capacity, the wet slag feeding quantity, hot air volume (heat) , dryer rotation speed (drying time) etc needs to achieve one balance point.

For detail of slag dryer working principle, you are welcome to contact Sunco Machinery at your convenience.