Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

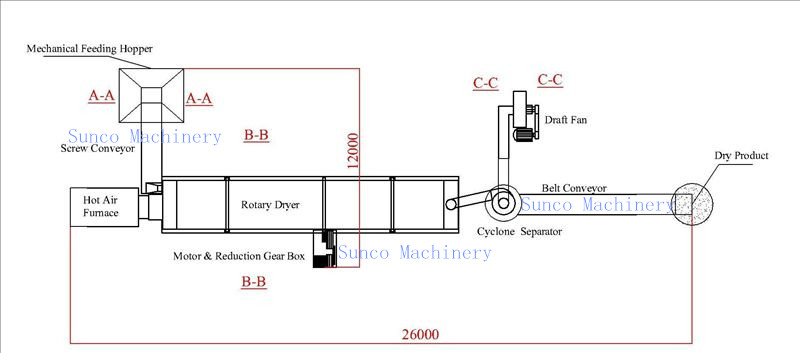

Output Capacity 2.0 Tons Per Hour Sawdust Drying Machine mainly consists of mechanical feeding hopper, inlet belt conveyor, rotary sawdust dryer, cyclone separator, high pressure draft fan, outlet belt conveyor, hot air furnace, electric control panel, etc.

The heat source for the Output Capacity 2.0 Tons Per Hour Sawdust Drying Machine can be as follows:

--- Waste wood

--- Coal

--- Natural Gas

--- Diesel

The work flow of the sawdust drying line is as follows:

01. Hot air furnace generates the high temperature air for the sawdust drying systems.

02. Tractor Shovel sends the wet sawdust into mechanical feeding hopper.

03. Mechanical feeding hopper sends the wet sawdust into belt conveyor.

04. Belt Conveyor sends wet sawdust into sawdust rotary dryer machine.

05. Rotary dryer machine not only supply the drying chamber for the wet sawdust, and also its reasonable inner structure help the hot air to heat and dry the wet sawdust sufficiently.

06. Cyclone separator is used to separate the wet sawdust from the exhaust air and water vapor.

07. Draft fan makes the high temperature air into the sawdust dryer machine, and make the sawdust and exhaust air into the cyclone separator.

08. Outlet belt conveyor takes the dry sawdust out of the sawdust rotary dryer.

09. Electric control panel is used to control all the above machines as need.

After being dried, the output moisture content of the dry sawdust can be reduced to be less than 15%. The dry sawdust can be used to produce high quality biomass pellets and boimass briquettes.

The sawdust rotary dryer by sunco machinery has the features as follows:

Sawdust Rotary Dryer is special designed Inner 7 Chamber, and it is Concurrent Dryer.

It has the advantages as follows:

01. New design by Sunco for drying low humidity material with surface water in bulk production.

02. Compact Structure, less space occupation.

03. Special 7 chambers inner design, when working, each part's weight of the dryer is balance. Less motor power needed.

04. The material will be flipped 7 times inside the dryer, and the flipping times is 2.3 times of the traditional drum dryer. Thus the material can be dispersed more sufficiently, and to be heated and dried by the hot air more sufficiently. As a result, the heat exchanging efficiency is higher, and its fuel consumption is lower.

05. The material falling height inside the dryer is reduced much, thus the material abrasion to the lifting plates and dryer drum is less.

06. Higher heat efficiency.

07. The material output moisture content can be controlled by adjusting the exhaust air temperature and the drying time in the dryer.

08. In actual operation, its water evaporation intensity is more than 2 times of the traditional dryer, thus it has higher heat efficiency, and the operation cost is lower.

09. It adopts Gear Drive with better stability .

Note: For Gear Drive type, can add lubrication oil between the roller and ring to reduce the friction, reduce the abrasion of roller and Ring.

For Roller Drive Type. it is use the friction between the Roller and Ring to transfer the power and make the dryer drum rotates, and it is not suitable to add lubrication oil between the Roller and Ring. Thus the abrasion of the Roller and Ring is much more, and its lifetime is shorter.

The dryer totally has 4 sets of Roller ASSY, and each set of Roller ASSY consists of 2 rollers. It means that totally there are 8 supporting point for the dryer machine, and the loading weight on each roller is only half of the loading weight on each roller of the traditional Triple Drum Dryer, thus it increases the running stability of the dryer machine.

If you are in need of Output Capacity 1.0 Tons Per Hour Sawdust Drying System, please supply more information as follows:

--- What is the usual initial moisture content (%) of your wet sawdust ?

--- What is the output moisture content (%) of the dry sawdust needed ?

--- What kind of fuel will you prefer to use for the sawdust drying system, such as coal, waste wood, diesel, or natural gas, etc ?

--- What is the output capacity (ton per hour) of the sawdust drying machine needed ?

For more detail of sawdust drying machine , please directly contact us:

--- Email: suncomachinery@hotmail.com

--- Tel./ WhatsApp: +86-15838214261