Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

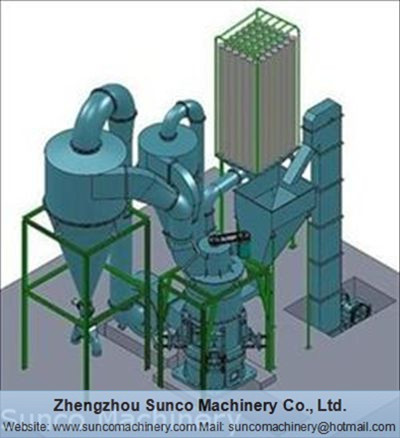

Powder grinder mainly consist of small jaw crusher , fine powder raymond mill, minearl powder classifier, cyclone powder collector, filter bag dust cleaner, high pressure blower, electrical control box, bucket elevator, storage hopper, and vibrating feeder, powder bagging machine.

The main application of the powder grinder is for super-fine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so on. The granularity of the end products is 30-325 meshes (0.613-0.044mm). Powder grinder system mainly consist of small rock crusher , raymond mill , powder classifier, powder collector, dust cleaner,high pressure positive blower, electrical control system, bucket elevator, storage hopper, and vibrating feeder and powder bagging machine.

Working principle of mineral powder grinder:

01. Raw material is crushed by jaw crusher to the size required which is suitable for the Raymond Mill ,

02. Then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for grinding mill. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind.

03. After this, the ground stuff are carried by the air from the blower into the powder separator (Analyzer Machine) for screening. The fine powers are blow into the cyclone powder collector and are poured out through the output-powder valve as the final products, and the corase stuff after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

Features of industrial powder grinder :

1. High efficiency

Under the same final size and power, the product capacity of powder grinder; industrial powder grinder is twice than jet mill and agitation mill.

2. Longer lifetime of spare parts

The roller and ring are made of special material, which improve the grinding efficiency a lot. For same material and final size, the lifetime of its wearing parts can reach to more than one year, about 2-5 times as long as that of vertical shaft impact crusher and turbo-mill. Especially when handling calcium carbonate and calcite, the lifetime can reach 2-5 years.

3. High safety and reliability:

4. High fineness of products

The product fineness can reach 0.033mm.

5. Environment friendly:

The application of dust collector reduce the pollution and noise of the dust, which has reached national environment protection standard.

Specification of industrial powder grinder:

odel | Roller Number | Roller Size | Maximum Feed Size (mm) | Fineness of Final Product (mm) | Output (t/h) | Main Frame Power (kW) | Blower Power (kw) | Overall Dimension (mm) |

5R4119 | 5 | 410×190 | 20-25 | 0.613-0.044 | 5-12 | 75 | 75 | 7850×8000×9700 |

4R3216 | 4 | 320×160 | 20-25 | 0.28-0.047 | 1.0-8.0 | 37 | 30 | 9900×5800×10580 |

3R2715 | 3 | 270×150 | 15-20 | 0.28-0.047 | 0.7-3 | 22 | 18.5 | 8700×5000×7819 |

3R2615 | 3 | 260×150 | 15-20 | 0.28-0.047 | 0.5-2.7 | 18.5 | 15 | 5650×3305×5950 |

3R2115 | 3 | 210×150 | 15-20 | 0.28-0.047 | 0.4-1.6 | 15 | 11 | 4500×2800×5800 |

3R1410 | 3 | 140×100 | 5-10 | 0.28-0.047 | 0.1-1.0 | 7.5 | 5 | 3200×2100×4500 |

Notice: Any change of industrial powder grinder technical data shall not be advised additionally.