Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Company News >

Hot! Bolivia client placed one order of Silica Sand Dryer Machine with production capacity 10 tons per hour, right now the related equipment is being manufactured now at Sunco Machinery Factory.

Bolivia client is our long term cooperation company and we have known each other since the year 2014. This time their project is to build one new cement mortar plant.

This cement mortar plant is to mix the sand, cement, additives, fillers, etc together according to the special ratio, and to produce high quality cement mortar in Bolivia.

Firstly needs to wash the quartz sand to get rid of the dust and impurity in advance, but then the sand will get wet. For the production of cement mortar, the moisture content of silica sand have to be less than 1% or even low. The drier is the better.

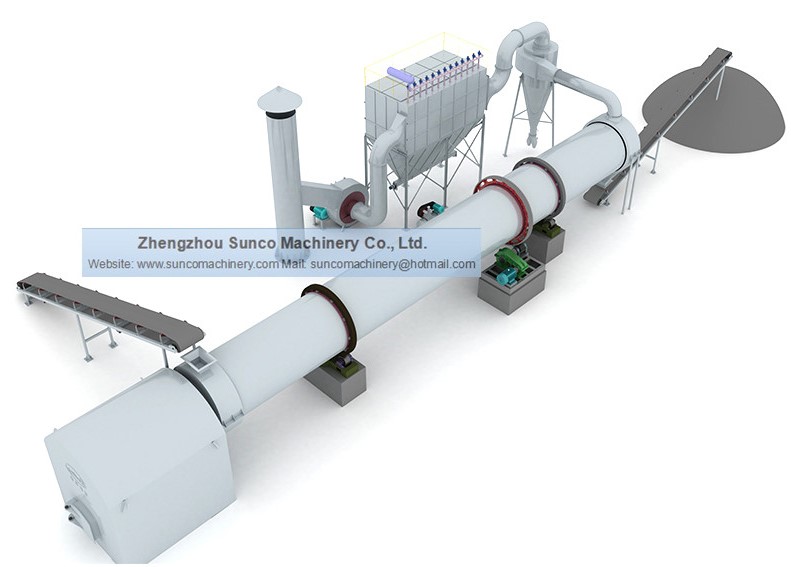

Silica Sand Dryer also is called quartz sand dryers, rotary sand drying machine, etc, and it is ideal for drying wet sand in large quantity, thus it is the key equipment for this cement mortar plant.

The whole work process of this new cement mortar plant is as below:

>>> Rotary Silica Sand Dryer is to heat and dry the wet quartz sand, and reduce its moisture content to be less than 1%.

>>> Vibrating Sieve is to classify the silica sand into different size ranges

>>> The different size range sand is stored into the related sand silios.

>>> By using belt weigher to feed the related sand, cement, filler, and additives into the mixer.

>>> Mixer machine one batch can mix about 3.5m3 material, and each batch takes about 15 minutes.

>>> After that, the bagging machine is to pack the high quality cement mortar into bags, and each bag weight is 25kg.

>>> There is one electric control cabient is used to control the whole cement mortar plant.

If you are in need of silica sand dryer machine or whole cement mortar plant, please feel free to contact Sunco Machinery at your convenience.

>>> Email: suncomachinery@hotmail.com

>>> WhatsApp/Mobile: +86-15838214261