Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Company News >

Chicken Manure Dryer is manufactured well for Nigeria customers, and it will be loaded into containers at factory on May 19th-20th.

The requirement information of Nigeria customers is as follows:

Raw Material: layer chicken manure;

Initial moisture content : about 60-70%;

Output Moisture Content: about 15%;

Input Capacity: 4 ton per hour;

Fuel: dry palm kernel shells.

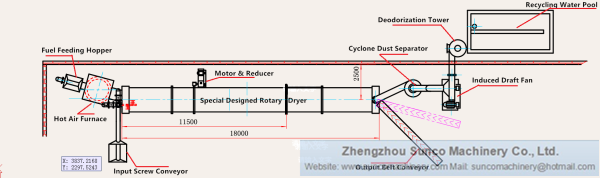

Work flow of Chicken Manure Drying System for Nigeria customers:

1. Hot Air Furnace is specially designed for burning the dry palm kernel shells, generate and supply the high temperature air for the chicken manure drying system.

2. Inlet Screw Conveyor sends the wet manure into the Chicken Manure Dryer.

3. Inside the chicken manure dryer machine, the wet manure is heated and dried by high temperature air sufficiently, and the moisture content of the manure is reduced to be about 15%.

4. Draft fan is used to make high temperature air into the drying machine, after heat exchanging process in the dryer, makes water vapor and exhaust air out of the dryer cylinder, and then goes into cyclone dust separator.

5. After being dried, wet manure become dry manure, most of dry manure come out from the outlet of the chicken manure dryer machine, and also some fine manure powder is mixed with the exhaust air, and then goes into cyclone dust separator. Cyclone dust separator is used to separate the dry manure powder from water vapor and exhaust air. Finally the water vapor and exhaust air come out from the top of cyclone dust separator, and then goes into deodorization tower; the fine dry manure powder falls down to the bottom of cyclone dust separator, and come out through wind closing device.

6. Deodorization Tower System is mainly used to get rid of the strong smell generated by chicken manure.

7. Outlet Belt Conveyor takes the dry chicken manure away from the chicken manure dryer machine.

8. Electric Control Cabinet is used to control all the machines in the chicken manure drying system.