Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Company News >

Good News! Input capacity 30 tons per hour slag drying machine for Taiwan Customers has been shipped today, and it is specially designed for drying mineral material such as slag, river sand, silica sand, quartz sand, etc.

The requirement information on the rotary slag dryer machine is as follows:

▋ Raw Material: Raw Slag from steel plant, 100% < 50mm, and about 50% < 10mm,

▋ Input moisture content about 18%-20%, loosen bulk density is 2200-2400kg per m3,

▋ Final output moisture content no more than 3%,

▋ Input Capacity 30 t/h,

▋ Output capacity 25.36 t/h.

▋ Fuel: LPG

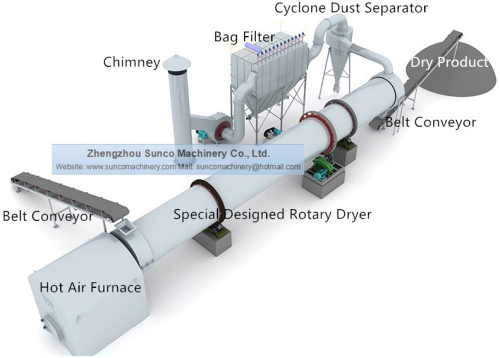

The workflow of capacity 30 tons per hour slag drying system is follows:

▋ Gas Burner and Hot Air Furnace supply the high temperature air for the slag dryer machine.

▋ Tractor shovel sends the wet slag into the Mechanical Feeding Hopper.

▋ Input belt conveyor sends the wet slag into the slag rotary drum dryer.

▋ Slag Rotary Drum Dryer is specially designed according to the features of the raw slag which is mainly surface water on the slag. Slag rotary drum dryer not only supply the drying chamber, but also help the hot air to heat and dry the wet slag sufficiently.

▋ Output belt conveyor takes the dry slag out of the slag rotary dryer.

▋ Cyclone separator is used to separate the fine dust from the exhasut air and water vapor.

▋ Draft fan makes the hot air into the slag dryer machine, and makes the exhaust air and water vapor out of the dryer machine.

▋ Electric control panel is used to control the above Slag Drying Plant.