Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Company News >

Warm Welcome Malaysia Mr.Chong visit Sunco for Wood Shavings Dryer Machine on June 12th.

The requirements of Malaysia Wood Shaving Dryer Machine Customer is as follows:

▍ Raw Material: Wood Shaving, Length 50mm x Width 25mm x Thickness 1.5mm, bulk density: about 40 kg per m3.

▍ Initial Moisture Content (%): 40%

▍ Output Moisture Content (%): about 12-15%

▍ Input Capacity of wood shavings dryer : 2500 kg/hour

▍ Fuel: waste wood

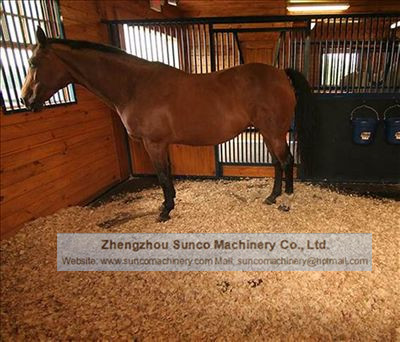

▍ End Use: bedding material for horse

Workflow of Wood Shaving Drying System:

▍ Fuel Burning Chamber and Fire-proof &Air distribution chamber are used to generate the high temperature air for the dryer machine.

▍ Tractor Shovel sends the wet wood shaving into Mechanical Feeding hopper.

▍ Input belt conveyor sends wet wood shaving into inlet feeder.

▍ High temperature Resistant Draft fan has the functions as follows:

(1)As the wood shavings is rather light, its help to make the wood shaving into dryer machine more smoothly.

(2)This draft fan is with one frequency conversion motor and air valve, by adjusting the cold air input quantity can adjust the temperature of hot air as need.

(3)This draft fan makes the hot air to contact and heat the wood shavings strongly here, and much of the water is evaporated into water vapor here.

▍ Inlet Feeder sends the wet wood shavings into the rotary dryer evenly, and also avoid the cold air into the dryer machine.

▍ Rotary wood shavings dryer not only supply the drying chamber, but also its help the hot air to heat and dry the wood shaving sufficiently, and get rid of the water, and finally reduce the moisture content of the wood shaving to the needed moisture content about 12-15%.

▍ Draft fan makes the hot air into the dryer, and makes the exhaust air and water vapor out of the dryer.

▍ Inside the cyclone separator the little fine powder is separated from the exhaust air. Finally the fine powder leave the cyclone separator through wind closing device, and fall down onto the outlet belt conveyor, and the exhaust air leaves the cyclone separator through top, then pass through the draft fan, and then goes into chimney, and finally goes into atmosphere.

▍ On the bottom of the dryer outlet there is one outlet feeder. This outlet feeder not only sends the dry wood shavings out of the dryer evenly, but also avoid the cold air into the dryer machine.

▍ Outlet belt conveyor takes away the dry wood shaving from the outlet feeder.

▍ Electric Control Panel is used to control the above wood shavings drying plant.