Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Company News >

Rotary Drum Dryer Working Principle:

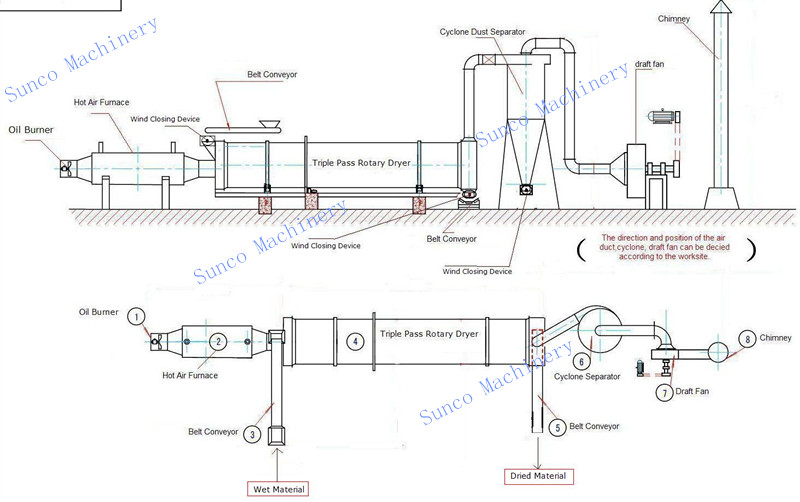

Wet material goes into the feeding hopper by belt conveyor or bucket elevator, then through the feeder goes into the feed pipe. The feed pipe slope is greater than the natural inclination of the materials, so that the material can inflow the rotary dryer smoothly.

There is one hot air furnace supply the hot flue gas for the rotary dryer usually. The fuel can be waste wood, coal, natural gas, diesel, etc.

The rotary dryer cylinder is tilted slightly compared with horizontal. Materials and hot flue gas goes into the rotary dryer cilinder from the higher end. During the rotation of the cylinder, the material by gravity goes into the lower end. When the wet material is in the process of moving forward in the rotary dryer cylinder body, the lifting plates inside the rotary dryer cilinder makes the material up and down to contact with the hot flue gas completely. Thus, the moisture inside the wet material is evaporated into water vapour, and finally we get the dried materials.

There is one high pressure induced draft fan is used to suck out the water vapour out of the rotary dryer during the drying process. Finally the water vapour with some dust goes into the cyclone dust collector. In the cyclone dust collector, the dust is seperated from the water vapour and falls down from the bottom of the cyclone dust collector; the water vapour leaves the cyclone dust collector from the top pipe of the cyclone dust collector, and finally goes into atmosphere through the chimney.

At the end of the rotary dryer, using one belt conveyor to transport the dried material into trucks or storage room directly.

The rotary drum dryer seems very simple, but in fact it is one whole drying system, and the drying system should be designed according to:

--- The features of raw material, for example the wet sand has surface water which is easier to be dried, but the wood chips has inner water which is more difficult to be dried.

--- Initial moisture content(%) of the wet material.

--- Output moisture content(%) the dried material needed.

--- Bulk density (kg per cubic meter) of the wet material.

--- Input capacity (ton per hour).

--- Output capacity(ton per hour).

--- Fuel Choice such as coal, waste wood, natural gas, diesel, etc.

--- End use of the dried product.

When the above information are clear, then Sunco Machinery engineers can calculate and design the suitable and reasonable rotary dryer system for the customers accordingly.

Sketch Map of Rotary Drum Dryer System:

Rotary Drum Dryer for drying chicken manure:

Rotary Drum Dryer for drying Sawdust:

Rotary Drum Dryer for drying Wood Chips:

Rotary Drum Dryer for drying Wood Shavings in Greece:

Rotary Drum Dryer for drying Sand in Malaysia:

Rotary Drum Dryer for drying slag in Malaysia:

For more details of rotary drum dryer working principle, please feel free to contact us:

Email: suncomachinery@hotmail.com

Website: http://www.suncomachinery.com/

Tel / WhatsApp: +86-158 3821 4261

YouTube: https://www.youtube.com/watch?v=i2GiO1HLn0A

http://www.youtube.com/watch?v=3K_Q819uqlQ&feature=youtu.be

https://www.youtube.com/watch?v=yGzcIJ0aFL0

https://www.youtube.com/watch?v=z1knBGM-3TM

http://www.youtube.com/watch?v=w6jA_YBLokM